The ability of 5000 voltages insulation in 1 minute is a basic character of insensitive electric pyrotechnics[1], for which the slapper squib must be designed. The slapper squib was made up of exploding foil, flyer, acceleration barrel, metal shell, charge, etc. As the minimum distance between the exploding foil and the metal shell of the slapper squib is only approximately 1.35 mm, the air gap between which is discharged when the voltage is less than 4000V[2]. Many methods had been tried, such as insulation coat and anode polarization of metal surfurce, exploding foil rounding, and so on. But none was done for high voltage of 5000V/1min. Through thoroughly analysis, we found that the most feasible way is cutting off the air channel between the exploding foil and the metal shell. In-situ formation of insulation flyer and gluing were two basic methods to cut off the air channel between the exploding foil and the metal shell.

In-situ formation of insulation flyer includes gas phase doposition and liquid flyer material coating. By gas phase doposition, the flyer material could be deposited on the surface of the exploding foil, but the density and adhesion force of the formed flyer were not so strong as the usual flyer, and this method needed complex and costly equipments[3]. Coating liquid flyer material on the exploding foil and solidification at about 300 ℃ was the other way, but converging of the liquid material to the center of the exploding foil while solidification was difficult to control, the flyer was not even and its thickness was not uniform.

The liquid, uncoagulated and heat melting gooey could be used to glue the flyer to the exploding foil[2]. The liquid gooey glued orbicular fringe of the flyer to the exploding foil, it functioned when controlled well. However, it was not easy to control well. As able to be flowing, it would flow to the center of the foil. As a result, the fire sensitivity of the slapper squib could be affected. The uncoagulated gooey could be a good choice as it is simple, insulates well and does not affect the ignition, howerver it affected the pressure output of the slapper squib. Until now, the heat melting gooey is the best choice, for it insulated well and could not affect the other performaces of the slapper squib. The principle of the method of the heat melting gooey and its effects on the performaces of the slapper squib were introduced.

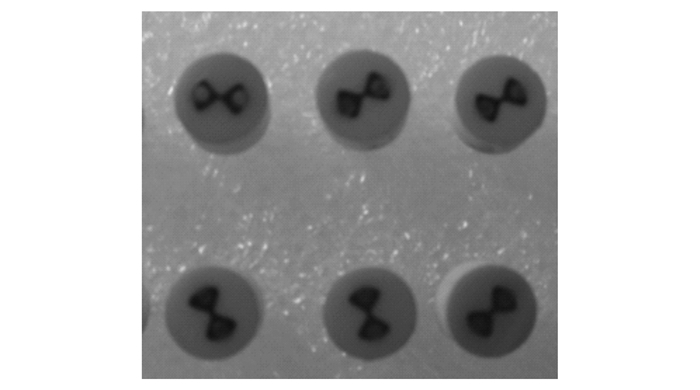

2 Experimental sampleThe heat melting gooey used is a kind of Polyimide-PI complex film, not stick and dry at normal temperature. And when heated to about 230 ℃, the complex film could be glued to surface of ceramic, metal and so on. And as it showed in Table 1, the PI complex film was comparable to the pure PI film on performances of insulation and mechanics, it might not affect the ignition and pressure output performace of the slapper squib. Based on these characteristics, it was used to cut off the air channel between the exploding foil and metal shell of the slapper squib and form an integrative part[4]. The samples made showed in Figure 1.

| Tab.1 Performances of the complex film and the pure film |

|

Fig.1 Sample of the assembly |

The resistance variation of the exploding foil after gluing at high temperature might affect the ignition of slapper squib. So the resistances before and after gluing were measured which showing in Table 2, there was no significant variation about the resistance after gluing.

| Tab.2 The resistance of the exploding foil before and after gluing |

Since the complex film could react with the exploding foil and the ceramic plug during long preservation to affect the igniton and insulation of the slapper squib, the resistance and apperance variation of the assembly of exploding foil and complex film could reflect this. The 71 ℃ accelerating ageing test[5] was used to simulate the long preservation, and as it shown in Table 3, there was no apparent change on the resistance and the appearance. According to GJB 736.8-90 Method of the test at 71 ℃, the life of the assembly at 25 ℃ is 22 years at least.

| Tab.3 The resistance and the appearance before and after 71 ℃ accelerating ageing test |

The igniton ability of the assembly of exploding foil and complex film was tested by "go" and "no go" method[6]. The assembly was used to initiate 1.55 g·cm-3 HNS-IV pellet by 0.3 μF capacitor discharge in the test. The results are in Table 4. Calculation based on the results shows 50% exploding peak current is about 1750 A, which is less than the slapper squib with usual film 300 A, owing to the integration and thinner film. The radius expansion decreasing of the the exploding foil plasma by integration and the thinner film can increase the impinging velocity of the flyer.

| Tab.4 The results of "go" and "no go" tests |

Five slapper squib with PI complex film were fired on various initiation current after 5000 V/1 min test. The output pressure of the pyrotechnics were measured in the close bomb of 0.6 cm3, and the result was shown in Table 5. It can be concluded that the complex film had no effect on the output performance of the slapper squib. Because even the initiation current less than 2500 A, the first peak pressures still satisfied the demanded 150 MPa to 230 MPa and the times of the first peaks still satisfied the demanded less than 200 μs, owing to the initiation ability increase of the exploding foil and flyer assembly.

| Tab.5 Pressure output of slapper pyrotechnics with complex film |

The complex film had no negative effect on the resistance, appearance, fire sensitivity and output performance, so it was pleasible for 5000 V/1 min of the slapper squib. Moreover, the complex film could improve the reliability of the slapper squib, simplify the assembly of the slapper squib and make the slapper squib be more adaptive to abnormal environment.

| [1] |

WANG Kui-quan, LI Yun-lai, XIAO Pei-rong. GJB 344A-2005. General design specification for insensitive electric-initiators[S]. 2005.

|

| [2] |

ZHU Ming-shui. Studies on insulation technology of slapper squib. GF-A1000917M[R], 2010.

|

| [3] |

CHAO Min, KOU Kai-chang, WU Guang-lei, et al. Advances in Vapor Deposition Polymerization Polyimide Films[J]. Material Review, 2009, 23(11): 118-122. |

| [4] |

TU Qiang, SHEN Hui-li, HU Shui-hua. Polyimide/Polyester-Imide Binding Film[J]. Insulating Materials, 2001(5): 24-26. |

| [5] |

LI Jing-song. GJB 736-90. Initiating Explosive device—method of the test at 71 ℃[S]. 1991.

|

| [6] |

LIU Bao-guang, XIAO Pei-rong, WU Qi-zhong, et al. GJB/Z 377A-94. Sensitivity test, statistical methods for[S], 1994.

|

A type of assembly of exploding foil and flyer, integrated polyimide complex flyer on exploding foil of slapper squib, can make the minitype slapper squib with full metallic shell satisfy the demand of 5000V/1min, and can improve the reliability and the shelf life of the slapper squib.