Superfine particles of explosives were researched for decades in order to obtain explosives with lower sensitivity and ameliorative initiating performances. Early investigations focused on the reduction of particle size and regulation of initiating performance[1-3]. Common methods included grinding of coarse particles and recrystallization of nanometer particles. The fresh-formed superfine particles owned really high surface energy and their aggregation were progressed within manufacture and application, which prohibited partially the advantage of superfine particles and counteracted the amelioration of initiating performances. Aggregation and anti-aggregation of superfine particles was confirmed vital gradually. In order to characterize the aggregation and its effects on the initiating performances, particle size is no longer the exclusive parameter and surface area becomes the more practical parameter in quality control[4]. Surface area could impossibly disclose the all of the actual microstructure of superfine particles and their conglomeration, and more details were expected for profound comprehension.

Fractal analysis, widely used in many areas of modern science[5], was introduced into explosives researches. Fractal phenomena were discovered early within the framing photographs of explosive samples under drop-hammer test[6-8], the fractal dimension was related to the impact sensitivity, and the sequential order of fractal dimension was in agreement with that of the drop hammer height for the six experimental explosives. Fractal phenomena were then found within the complicated surface of TATB-binder particles under AFM (atomic force microscopy) in situ heating observation[9] which might be relevant to activation and crystallization of binder. Fractal characteristics of molecular-crystal structure of TATB explosive were found relative to their manufacture method[10]. Fractal analysis was found feasible within particle size distribution and morphological measurements of HMX, RDX, and PBX9501 explosives[11].

Fractal phenomena were also found in our experiments of grinding of BNCP (tetraammine-bis-(5-nitro-2H-tetrazolato-N2) cobalt (Ⅲ)-perchlorate) explosive[12]. Fractal dimensions of particle size distribution of particles increased during grinding and did not increase any longer when mean particles size decreased to less than ten micron. It was deemed that quantity of submicron and nanometer particles should aggregate and formed lower density conglomeration which introduced abnormality into fractal dimension calculation assumption. In other words, fractal dimension could be relative to decrease of particle size and aggregation of superfine particles.

In the context, microstructure of TATB and HNS superfine explosives was studied including the aggregation of nanometer crystals, the desorption isotherms of both conglomeration samples, their fractal characteristics, and etc.

2 Experimental 2.1 Preparation of Superfine Particles and Conglomeration SamplesHNS superfine particles were prepared according to literature [2]. Hot HNS/DMF(dimethyl formamide) solution were sprayed rapidly into cryogenic deionized water to promote nucleation and prohibit nucleus growth so that majority of HNS precipitated with submicron and nanometer size. These superfine particles aggregated to form conglomeration sample during washing with quantity of deionized water and dehydrating under room temperature.

TATB superfine particles were prepared similarly according to solvent-nonsolvent recrystallization method[3]. Hot TATB/concentrated sulfuric acid solution was sprayed rapidly into cryogenic deionized water and majority of TATB precipitated with submicron and nanometer size. These superfine particles aggregated to form conglomeration sample during washing with quantity of deionized water and dehydrating within vacuum freeze-drying machine.

2.2 Morphology and Microstructure AnalysisThe surface morphology of the conglomeration samples were measured with TM1000 scanning electron microscope.The microstructures data of the conglomeration samples were measured with Quantachrome nova automated gas sorption system.

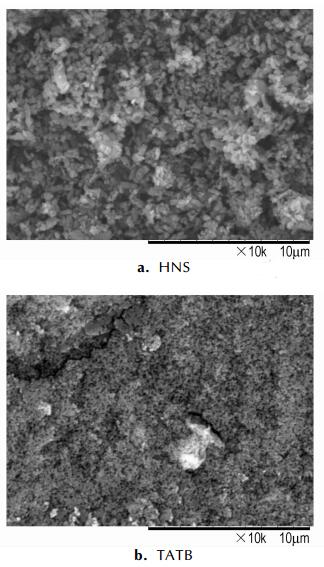

3 Results and Discussion 3.1 Morphology and Surface AreaThe conglomeration sample was observed to consist of nanometer crystals as given in Fig. 1. HNS conglomeration sample consisted of cashew-like nanometer crystals with their length less than 1 μm, their diameter round several hundred nanometers, and length-diameter ratio round 3:1-4:1. These nanometer crystals piled up tightly here or loose somewhere else to form the conglomeration sample.TATB conglomeration sample consisted of nanometer crystals with their length and diameter smaller than that of HNS. These TATB crystals connected mutually to form framework-like conglomeration as in literature [13].

|

Fig.1 SEM micrograph of conglomeration sample of HNS and TATB |

HNS conglomeration were measured up to 11.8 m2·g-1 (correlation coefficient 0.99966) which was close to literature[14-15]. TATB conglomeration were measured up to 24.77 m2·g-1 (correlation coefficient 0.99987). It was in accordance that TATB conglomeration sample consisted of smaller crystals and owned higher surface area than HNS did. Besides, application of freeze-dryer dehydration within manufacture of TATB sample would prohibit aggregation of nanometer crystals better than room temperature dehydration within manufacture of HNS sample.

The surface area of conglomeration sample was assumed vital to sensitivity of explosives[16] and higher surface area should be obtained with milder aggregation under more skilled manipulation and milder aggregation within recrystallization, washing and dehydration. After all, aggregation should be only prohibited and not avoided entirely.

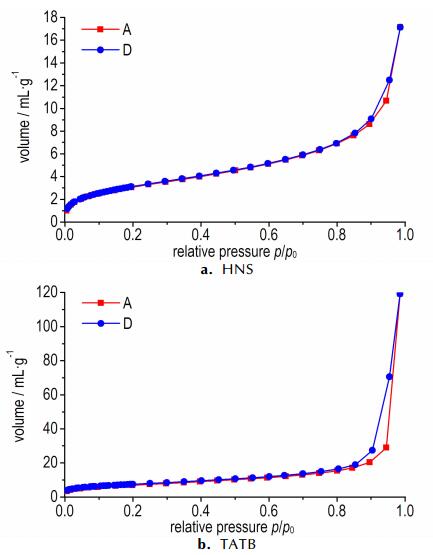

3.2 Desorption Isotherm and Fractal AnalysisBoth the two conglomeration samples showed Ⅳ type desorption isotherms as given in Fig. 2. HNS sample showed smaller hysteresis loop within range of high relative pressure(p/p0) 0.8-1 and TATB sample showed bigger hysteresis loop with slimly wider relative pressure range 0.7-1. The difference between two isotherms was in accordance with their preparation techniques: freeze-dryer dehydration within TATB preparation might prohibit collapse of space between nanocrystals more effectively during sublimation of moisture and led to more porous microstructures than room temperature dehydration within HNS preparation.

|

Fig.2 Desorption curves of conglomeration sample |

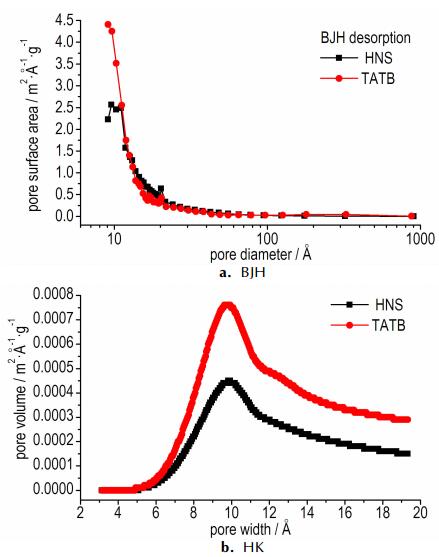

Barrett-Joyner-Halenda(BJH) and Horvaih-Kawazoe(HK) desorption curves of the conglomeration samples was given in Fig. 3 with approximately similar profile. BJH curves of TATB sample showed higher pore volume and higher surface area before 12 Å and after 80 Å than that of HNS, while it was reverse within range of 12-80 Å. It was obvious that total surface area from BET methods should be in accordance with not details but the integration of isotherm. BJH and HK desorption curves also showed that micropores contributed to pore volume more than mesopores.

|

Fig.3 BJH and HK curves of two conglomeration samples |

Microstructures of conglomeration samples were analyzed with fractal analysis. Fractal dimension was calculated according to desorption curve in Fig. 2 and Avnir-Jaroniec method[17] as followed:

| $ \ln (\mathit{n}){\rm{ = const-(3-}}\mathit{D}{\rm{)ln(}}\mathit{A}{\rm{)}} $ | (1) |

| $ \mathit{A =-RT}{\rm{ln(}}\mathit{p}{\rm{/}}{\mathit{p}_{\rm{0}}}{\rm{)}} $ | (2) |

where D is the value of fractal dimension, n is molar amount of adsorbate adsorbed at the relative pressure p/p0 and absolute temperature T(K), R is equal to 8.314 Pa·m3·mol-1·K-1 and A is the so-called adsorption potential defined as in formula (2).

The ln(n)-ln(A) fitted beeline very well with high correlation coefficients within p/p0 range of 0. 005-0.2 and the slope of beeline should lead to fractal dimension (D) as described in Table 1. D is lower within p/p0 range of 0.005-0.04, medium within 0.04-0.10, and higher within 0.10-0.20. Furthermore, fractal dimension of HNS revealed lower than that of TATB which accorded with the truth that TATB conglomeration sample owned abundant micropores and higher surface area.

| Tab.1 Fractal dimension data calculated from desorption data |

Superfine explosives were well-known for decades due to its expectant improvement for sensitivity and initiating performances. Early researches of superfine explosive focused on the reduction of particle size which worked intuitively on performance modification. Subsequent experience showed that superfine particles with similar particle size distribution would not always lead to expectative performance and the disturbance should result considerably from conglomeration. Surface area which summarized the particle size distribution and some of the conglomeration was then brought forward. The experiments showed that surface area should be more relevant than particle size to sensitivity and initiating performances of superfine explosives so that surface area turned to be major quality parameter in manufacture[15-16]. Unfortunately, surface area could not explain everything and there were some other parameters which regulated the sensitivity and initiating performance.

According to classical hotspot theory[18], initiation of non-homogeneous explosives consisted of initiation of hotspots and growth of explosion, initiation of hotspots should be more difficult while growth of explosion should be easier for superfine explosives than for ordinary explosives. When the superfine explosives were attempted in flyer impact experiments, shockwave pressure was far higher than necessary for initiation of hotspots and growth of explosion dominated within the initiation process. Therefore, flyer impact experiments[19-21]showed lower initiating voltage and lower initiating energy threshold for superfine explosives than ordinary explosives.

How to describe microstructure of superfine explosives? The parameters in existence such as particle size distribution and surface area should be expected to relate to the novel parameters supplemented in the text including BJH data, HK data, and fractal dimension. These should be expected beneficial to comprehension of microstructure-initiating performance relationship of the explosives though their relationship was not discussed sufficiently.

Microcosmic structure should play an important role from creation of hotspots to eyeable explosion. The microstructure parameters should be relevant to both the hotspots distribution and the growth of explosion. The sequent researches would be expected to detailed the relationship of microstructure and macroscopical initiating performance. There might be new-fashioned parameter which acted better in quality control and initiating performance.

4 ConclusionsMicrostructure of superfine explosives conglomeration were detailed. HNS conglomeration consisted of cashew-like nanometer crystals which piled up tightly here or loose somewhere else to form the conglomeration sample and the surface area was measured up to 11.8 m2·g-1. TATB conglomeration consisted of nanometer crystals which connected mutually to form framework-like conglomeration and the surface area was measured up to 24.77 m2·g-1. Both samples showed Ⅳ type desorption isotherms with their hysteresis loop ranged within really high pressure. BJH and HK curves showed higher pore volume and higher surface area before 12 Å and after 80 Å for TATB conglomeration than for HNS, while it was reverse within range of 12-80 Å. It seemed that micropores contributed to pore volume more than mesopores.

Desorption isotherm of both conglomeration samples were analyzed to show fractal characteristics. The fractal dimension behaved lower within the range of p/p0 0.005-0.04, medium within 0.04-0.10, and higher within 0.1 -0.2. Comparatively, TATB sample owned higher fractal dimension than HNS sample.

The microstructures of superfine explosives conglomeration should be researched more and new-fashioned parameter might be expected to act better in quality control and initiating performance.

Acknowledgement: This work was sponsored by ICM-CAEP. Thanks are due to WANG Ping and QIAO Zhi-qiang for their assistance in preparation of superfine samples.| [1] |

Teipei U, Bremser J K. Particle Characterization In Energetic Materials[M]. Weinheim: Wiley-VCH VerlagGmbH & Co. KGaA, 2005.

|

| [2] |

Thorpe R, Feairheller W R. Development of processes for reliable detonator grade very fine secondary explosive powders. NTIS: DE88-012863[R], 1988.

|

| [3] |

Feairheller W R, Donaldson T A, Thorpe R. Recrystallization of HNS for preparation of detonator grade explosive material, NTIS: DE88012862[R], 1989.

|

| [4] |

Military Specification Explosive HNS-Ⅱ and HNS Ⅳ[S]. US military standard MIL-E-82903(OS), 1999.

|

| [5] |

Bunde A, Havlin S, E ds. Fractal in science[M]. Berlin: Springer-Verlag, 1994, 1-26.

|

| [6] |

LIN Qi-wen, XIA Xian-gui, YANG Guang-zhi, et al. Investigation on impact sensitivity of explosive with fractal geometry[J]. Chinese Journal of High Pressure Physics, 1999, 13(1): 64-70. |

| [7] |

ZHANG Guan-ren. Application of fractal geometry to dynamic impact testing of condensed explosives and other materials[J]. Propellants, Explosives, Pyrotechnics, 1996, 21: 166-168. DOI:10.1002/(ISSN)1521-4087 |

| [8] |

ZHANG Guan-ren. Fractal and shock sensitivities of condensed explosives[J]. Explosion and Shock Waves, 1994, 14(2): 105-111. |

| [9] |

Cheng K, Liu X, Guan D, Xu T, et al. Fractal analysis of TATB-based explosive AFM morphology at different conditions[J]. Propellants, Explosives, Pyrotechnics, 2007, 32: 301-306. DOI:10.1002/(ISSN)1521-4087 |

| [10] |

XIA Qing-zhong, CHEN Bo, ZENG Gui-yu, et al. Experimental investigation of insensitive explosive C6H6N6O6 by small angle X-ray scattering technique[J]. Acta Physica Sinica, 2005, 54(7): 3273-3278. |

| [11] |

McAfee J M, Nelson R A. Explosive morphology from fractal analysis of micrographs. NTIS: DE99002824/XAB[R], 1999.

|

| [12] |

YU Wei-fei, HUANG Hui, CHEN Y, et al. Fractal characteristics on particles size distribution of superfine BNCP explosive[J]. Chinese Powder Science and Technology, 2009, 15(1): 31-34. |

| [13] |

YANG Guang-cheng, NIE Fu-de, HUANG Hui, et al. Preparation and characterization of Nano-TATB explosive[J]. Propellants, Explosives, Pyrotechnics, 2006, 31(5): 390-394. DOI:10.1002/(ISSN)1521-4087 |

| [14] |

WANG Jing-yu, HUANG Hao, XU Wen-zheng, et al. Prefilming twin-fluid nozzle assisted precipitation method for preparing nanocrystalline HNS and its characterization[J]. Journal of Hazardous Materials, 2009, 162(2-3): 842-847. DOI:10.1016/j.jhazmat.2008.05.107 |

| [15] |

WANG Ping, QIN De-xin, NIE Fu-de, et al. Study on the preparation technology of ultrafine HNS[J]. Chinese Journal of Energetic Materials(Hanneng Cailiao), 2001, 9(4): 153-155. |

| [16] |

YU Wei-fei, CHEN Ya, NIE Fu-de. Effect of surface area on sensitivity and properties of BNCP superfine particles[J]. Chinese Journal of Energetic Materials(Hanneng Cailiao), 2008, 16(5): 519-524. |

| [17] |

Jaroniec M. Evaluation of the fractal dimension from a single adsorption isotherm[J]. Langmuir, 1995, 11: 2316-2317. DOI:10.1021/la00006a076 |

| [18] |

Bowden P P, Yaffe A D. Initiation and growth of explosion in liquids and solids[M]. London: Cambridge University Press, 1952.

|

| [19] |

TAN Ru-mei, TAN Ying-xin, WU Yong-wei. Experimental research of flyer initiating performances of fine explosives[J]. Journal of Sichuan Ordnance, 2005, 2: 45-46. |

| [20] |

LEI Bo, SHI Chun-hong, MA You-lin, et al. Preparation and Characterization of Ultrafine HNS[J]. Chinese Journal of Energetic Materials(Hanneng Cailiao), 2008, 16(2): 138-142. |

| [21] |

LI Zhi-peng, ZENG Gui-yu, LIU Lan. Influences of microstructure on detonation-spreading performances of TATB-based explosives[J]. Explosion and Shock Waves, 2009, 29(06): 665-669. |

Microstructures and fractal characteristics of two superfineexplosives conglomeration were researched.