Polymer bonded explosive (PBX) is one of the most commonly used energetic materials in which explosive crystals are bonded in a binder system. The response of such materials to mechanical stimuli is of big importance in achieving a fundamental understanding of sensitivity, ignition and even detonation. There are many published experiments characterizing its constitutive behavior under simple (single) loading conditions but little attention has been paid to its loading-history related properties. As one kind of particle-filled elastomers, PBX may also exhibit phenomena such as stress softening (also known as the Mullins effect[1-2]), hysteresis and residual strain under cyclic loading, which indicates it a loading-history dependent composite. Due to the highly-filled material nature, mechanical properties of PBX are also strongly influenced by deformation rate. These phenomena must be noticed when we try to derive a robust, or physically-based constitutive model for PBX′s application, especially noting most of them remain poorly understood. Hence, it is necessary to understand and model its complex phenomenology including both loading history and loading rate.

When a particle-filled elastomer is subjected to mechanical loading, its inherent mechanical properties are then changed and internal damage activated. The degree of the alteration and damage can be determined by subsequent unloading and reloading response, which has been evidenced by large numbers of work in various filled materials[3-7]. This method is of special value to predict performance and damage evaluation of energetic materials for usage safety. In the work of Canga et al[8], a closed stress-strain path with residual strain and softening was observed during a cyclic tension test of solid propellant. They also proposed a damage model with a cyclic loading function to identify the effect of hysteresis, which meant energy dissipation in the loading-unloading progress. Gratton et al[9] investigated the cyclic behavior of an octahydro-1, 3, 5, 7-tetranitro-1, 3, 5, 7-tetrazocine (HMX) based PBX in both compressive and tensile deformation loading. Residual strain in the two conditions was found to increase with increasing loading amplitudes, yet this is out of their focus. The nonlinear response, especially unloading and hysteretic behavior, was not well modeled. Le et al[10] also introduced cyclic loading conditions to underline the elastic properties of a quasi-brittle material composed of HMX and a binder. In this article, the phenomena of damage, residual strain, and time dependence were characterized using a Maxwell′s model, with all the components set to be affected by an isotropic damage. Yeom et al[11] introduced a pseudo-elastic phenomenological model for PBX explosive containing stress softening effect, but the behavior of residual strain was also not considered in their work.

In addition to the effect of loading history, the loading rate dependence of PBX has been one of the subjects of energetic materials, which has already been extensively investigated in compression[12] and tension[13]. These experiments revealed how the applied loading rates had influence on the stress-strain response in the loading progress. For example, most PBXs were found to exhibit increasing elastic modulus, maximum flow stresses and strain-at-maximum stress (or failure strain), with increasing strain rates.

Since the loading-history related properties of PBX are not well-studied, the effect of loading rate on cyclic behavior also remains unknown. We draw support from other micro-structurally similar materials, especially rubbers, which share similar mechanical behavior as cast PBXs. Kraus et al14] investigated the stress-softening of a carbon black-reinforced rubber under different extension rate, indicating that stress-softening was loading rate dependent. Cheng and Chen[15] observed increased stress levels at both loading and unloading curve for increased loading rates in ethylene-propylene-diene terpolymer (EPDM) rubber experiments. Moreover, they also found that the effects of loading rate and maximum stretch on stress-softening were independent of each other. In the work of Boyce for poly(ethylene terephthalate) (PET), residual strain is depicted to depend on strain rate, strain and temperature[16].

In this work, quasi-static compressive tests with different loading rates are conducted to investigate the loading-history and loading-rate effects of a cast PBX. A constitutive model developed by Dorfmann and Ogden[17], which is based on strain energy function and pseudo-elasticity theory, is employed to describe the stress-softening and residual strain effect at various loading rates.

2 ExperimentalThe PBX explosive employed in this investigation is composed of hexahydro-1, 3, 5-trinitro-1, 3, 5-triazine(RDX) and aluminum in a hydroxyl-terminated polybutadiene(HTPB) based binder system. Before machining, the material has to go through the following fabricating procedures, including mixing, vacuum casting and cure. Cylindrical samples were finally received with 20 mm in diameter and 20 mm in long, with average density of 1.71 g·cm-3.

Quasi-static uniaxial compressive experiments were conducted using an INSTRON test machine (model 5969), in which force data and cross-head displacement were obtained with respect to time for individual specimen. Stress and strain information can then be calculated from the recorded data conjugating with measured specimen dimensions. In this experimental investigation, separate loading rates were applied to compression cycles (0.12, 1.2, 12 mm·min-1), whose corresponding strain rates were 10-4, 10-3/s and 10-2/s, respectively. Here the strain rate is calculated by

Grease was used as lubrication to reduce friction effect between the specimen and testing compression plates. The deformation history of the PBX captured by a CANON camera is shown in Fig. 1. With increase of time, the specimen maintained a cylindrical shape, indicating friction was an insignificant factor here and uniaxial compressive deformation achieved.

|

Fig.1 Deformation history of the cast PBX with increase of time |

In this section experiments were performed to evaluate the effect of loading rates and previous applied maximum strains on the stress-strain behavior of the PBX. The stresses expressed in this paper are all engineering stresses, which are the ratio of axial force to the initial cross-sectional area of a specimen, and the strains are engineering strains, which are the changes of length on per unit of undeformed length. Compression is taken as negative during our analysis.

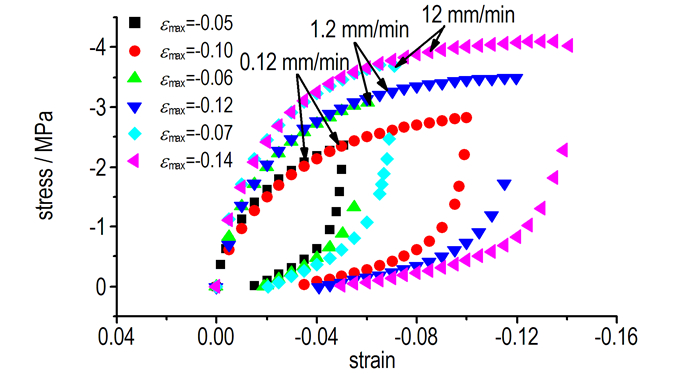

Specimens were first subjected to a loading-unloading test with different maximum strains and loading rates: maximum strains of -0.05 and -0.10 at 0.12 mm·min-1, maximum strains of -0.06 and -0.12 at 1.2 mm·min-1, and maximum strains of -0.07 and -0.14 at 12 mm·min-1. These tests were aimed at giving an essential view of mechanical characteristics of the cast PBX under periodic loading. The results of stress-strain response are represented in Fig. 2, which clearly shows the existence of stress softening, residual strain and loading rates effect. Compared to cyclic behavior of elastomers (e.g., rubber materials[15] and biological materials[16]), the PBX has similar performance but appears some distinctions.

|

Fig.2 Stress-strain loops of the cast PBX at different quasi-static strain rates |

The PBX exhibits strain hardening behavior with no prominent yield point in the loading path, at the illustrated strain levels. When unloading begins, stresses undergo a steep descend around the maximum strains, leaving the unloading curves well beneath the primary loading curves, namely, a hysteretic response, as shown in Fig. 2. It is noted that the hysteresis here is not crescent-shaped like that of rubber materials but sharp-oval-shaped.

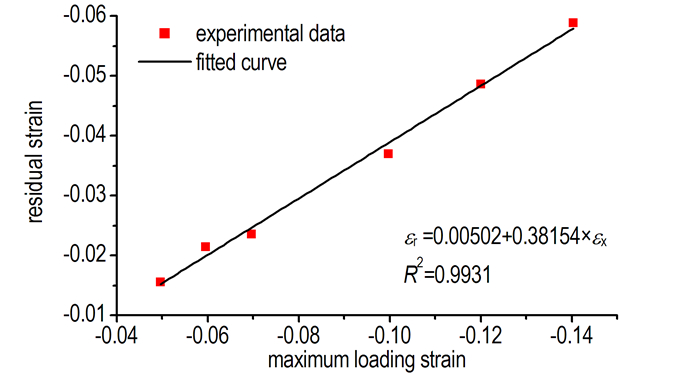

Obvious residual strains are observed in all experiments of this series, that is to say, when the compressive stress is unloaded to zero, the specimen can not return to its primal shape. As revealed in Fig 2, residual strain tends to associate with the maximum loading strain. Their linear relationship is shown in Fig. 3, from which we can see increasing maximum strain translates into increasing residual strain. Since residual strain can be considered a damage signal of the PBX, it is indicated that material damage here is more sensitive about the maximum loading strain than loading rate.

|

Fig.3 Residual strain versus maximum loading strain for the cast PBX (εr-residual strain, εmax-maximum loading strain) |

Loading rate effect is an important factor to be considered. The stress levels, both at the loading and unloading processes, are expected to increase as the loading rate increases. This increase thus gives rise to an expansion of the area enclosed by the stress-strain loops, which means the loading-unloading cycle dissipates more energy at a higher loading rate.

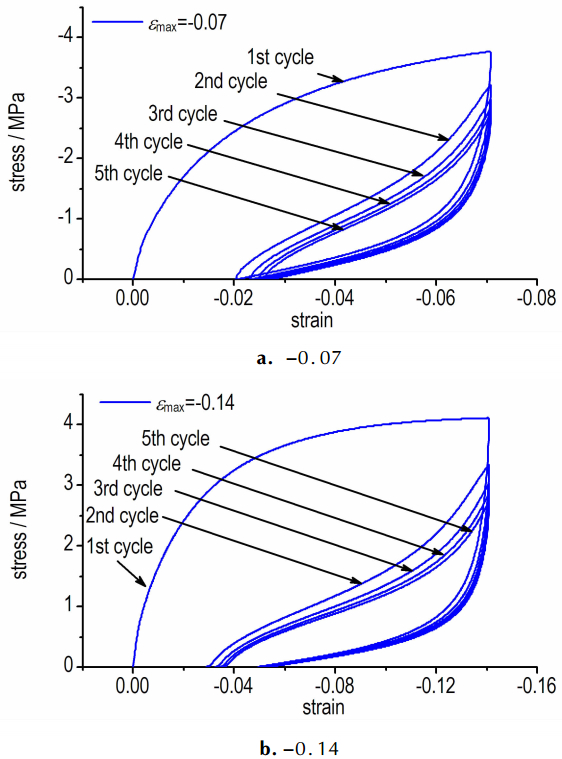

Cyclic loading experiments were then conducted to gain more details about loading-history related characteristics of the PBX, in which specimens were compressed to fixed maximum strains of -0.07 and -0.14 at a loading rate of 10-2/s. The stress-strain history of the first loading cycle has already been shown in Fig. 2. Here the following four cycles are also plotted, as shown in Fig. 4. When the specimen is reloaded in the second cycle, the loading-unloading cycle go through a new path, well below the previous one. That is the stress softening phenomenon in the specimen, which is most significant between the first two cycles. Besides, the shape of the hysteresis has been changed. A new different crescent hysteresis is formed from this cycle and the area of the hysteresis is much smaller than that of the first loading cycle. We ascribe the attenuate of the hysteresis, which means the ability of energy absorption, also to internal damage of the material over a loading cycle. Moreover, the stress cannot yet return to the highest level at the maximum loading strain during reloading, indicating a decreased strength of the material. After unloading is finished in a loading cycle, a residual strain left. The residual strain has an accumulation on the basic value of the first cycle and larger previous loading strain leads to larger residual strain. Just as respected, the behavior of stress softening, hysteresis and residual strain all decays gradually from the first loading-unloading cycle. The PBX can reach an approximately stable state after about five cycles at a fixed maximum loading strain.

|

Fig.4 Stress-strain loops with different fixed maximum strain at 10-2/s strain rate |

The modeling of stress softening, incorporating residual strain and loading rate effect is an extensively investigated topic for elastomers in the last few decades. These models are mainly based on experiments under quasi-static loading. Although it is difficult to explain the mechanism of loading-unloading behavior even for rubber, there have been many works in quasi-static condition. Most of the initial efforts only cover stress softening effect, for example, the work in references [2, 18, 19]. Later the residual strain behavior is taken into account, representative example being the phenomenological model of Dorfmann and Ogden[17]. This model is based on the theory of pseudo-elasticity and has been widely employed to characterize the loading-history related behavior of particle-filled elastomers[7, 15, 17].

Because it is rather difficult to model all the loading-history and loading-rate effects related to cast PBX, we mainly focus on the stress softening and residual strain characteristics. As a trying in energetic materials, the modeling of stress softening and residual strain can give us a new sight on the damage mechanism of PBX. In this section Dorfmann and Ogden′s theory is used to describe the stress-strain behavior of the cast PBX tested in our experiments. For the sake of simplicity, here we just list some pivotal parts of the theory and more details we refer to references [17] and [20].

On the basis of pseudo-elasticity, Dorfmann and Ogden wrote engineering stress σ under simple loading as

| $ \sigma = {\eta _1}\frac{{\partial {W_0}(\lambda )}}{{\partial \lambda }} + (1 - {\eta _2})\frac{{\partial N(\lambda )}}{{\partial \lambda }} $ | (1) |

Where λ is the stretch radio equal to 1+ε, ε is the engineering strain; the function W0 is the strain energy function and the function N is introduced here to describe the residual strains. η1 is referred to as a softening variable and η2 is named as a residual strain variable, respectively. In their study the function W0 was expressed by

| $ {W_0} = \sum\limits_{i = 1}^3 {\frac{{{\mu _i}}}{{{\alpha _i}}}({\lambda ^{{\alpha _i}}} + 2{\lambda ^{{-\alpha _i}/2}} - 3)} $ | (2) |

And the function N was represented by[17]

| $ N(\lambda ) = \frac{1}{2}[{\kappa _1}({\lambda ^2} - 1) + 2{\kappa _2}({\lambda ^{ - 1}} - 1)] $ | (3) |

μi and αi (i=1, 2, 3) in Eq.(2) and κ1, κ2 in Eq.(3) are material parameters to be determined by experiments. κ1, κ2 and μi are all in MPa. Then, from Eq.(1)-(3), the engineering stress is now given by

| $ \sigma = {\eta _1}\sum\limits_{i = 1}^3 {{\mu _i}({\lambda ^{{\alpha _i} - 1}} - {\lambda ^{ - {\alpha _i}/2 - 1}}) + (1 - {\eta _2})({\kappa _1}\lambda - {\kappa _2}{\lambda ^{ - 2}})} $ | (4) |

During primary loading, the softening variable and residual strain variable are inactive that η1=η2=1. When unloading is initiated, the two variables are activated and depend on the maximum strain energy Wm in the loading progress. Still by Dorfmann and Ogden [17], the expression of η1 is

| $ {\eta _1} = 1 - \frac{1}{r}\tan \mathit{h}\left[ {\frac{{{W_{\rm{m}}} - {W_0}(\lambda )}}{{\mu m}}} \right] $ | (5) |

Where r and m are two positive material parameters, tanh(*) is the hyperbolic tangent function. The shear modulus μ can be calculated from

| $ \mu = \frac{1}{2}({\mu _1}{\alpha _1} + {\mu _2}{\alpha _2} + {\mu _3}{\alpha _3}) $ | (6) |

The residual strain effect is determined by

| $ {\eta _2} = \tan \mathit{h}\left[ {{{\left( {\frac{{{W_0}(\lambda )}}{{{W_{\rm{m}}}}}} \right)}^{\gamma ({W_{\rm{m}}})}}} \right]/{\rm{tan}}\mathit{h}{\rm{(1)}} $ | (7) |

The exponent γ(Wm) ≥0 describes the influence of residual strain effect on the subsequent unloading stress. It is noted that the value of η1 and η2 are between 0~1 from Eq.(5) and Eq.(7). When λ=1 Eq.(4) simplifies to

| $ \sigma = {\kappa _1} - {\kappa _2} $ | (8) |

The σ in Eq.(8) must be positive for simple compression.

The model is used here in this work to describe the stress-strain behavior of PBX sketched in Fig. 2. Material parameters in Ogden function Eq.(2) are determined with the primary loading curve, whose values are listed in Table 1. The fitting method we used here is the Least-square algorithm. Using Eq.(6), we obtain μ=56.92 MPa at the stretch rate of 10-3/s. Fig. 5 shows the comparison of experimental data and numerical results. Then, the softening parameters of Eq.(5) are determined by two unloading curve with different maximum stretch (0.94 and 0.88), giving the value r=1.838 and m=2.52E-04. Similar to the result of Dorfmann[17], the exponent in Eq.(7) does not keep constant, but linearly increases with the strain energy function

| $ \beta = 3.1623 + 4.9633{W_{\rm{m}}} $ | (9) |

| Tab.1 Parameters of Ogden model for loading path of the PBX (strain rate 10-2/s) |

|

Fig.5 Comparison of the experimental data and the theoretical prediction results during loading |

Finally, κ2 is determined to be -0.104 and κ1

| $ {\kappa _1} = 0.37649 + 7.1237(1 + {\lambda _{\rm{m}}}) $ | (10) |

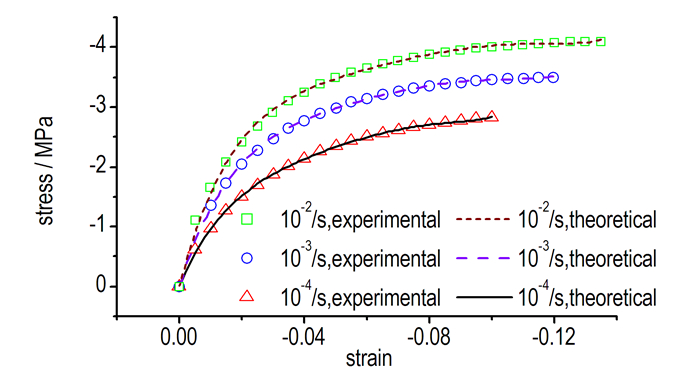

These parameters are used to predict the loading-unloading behavior of the PBX, with results presented in Fig. 6a. The shear modulus μ at strain rates 10-4 and 10-2/s are 43.94 and 71.93 MPa, respectively, with results presented in Figs. 6b and 6c. It is shown that the Dorfmann and Ogden′s model can be well used to describe the stress-softening and residual strain phenomena of PBX.

|

Fig.6 Comparison of the experimental data and the theoretical prediction results during unloading |

We presented experimental results and phenomenological modeling of a cast PBX under cyclic quasi-static deformation conditions. The phenomena of stress softening and hysteresis during cyclic loading, and residual strain upon unloading demonstrated that the mechanical properties of the material were affected not only by loading rates, but also by the stress-strain history. The residual strain and hysteresis are more sensitive to the loading history than loading rates, the former of which is found to linearly increase with increasing maximumstrain. It has indicated that, at least in quasi-static deformation conditions, the internal damage of PBX is controlled mainly by the maximum strain.

Dorfmann and Ogden′s theory was used to characterize the stress-strain behavior at various maximum strain and loading rates. In our analysis, the rate effects are considered to be associated only with the material properties, thus only the parameter μ in Eq.(6) is a function of strain rate. The fitted values of μ are 43.94, 56.92 MPa and 71.93 MPa at 10-4, 10-3/s and 10-2/s, respectively. Constitutive model based on this assumption can give a good prediction on the cyclic behavior containing stress softening and residual strain of the PBX.

| [1] |

Mullins L. Softening of rubber by deformation[J]. Rubber Chemistry & Technology, 1969, 42(1): 330-362. |

| [2] |

Mullins L, Tobin N R. Stress softening in rubber vulcanizates. Part 1, Use of a strain amplification factor to describe the elastic behaviour of filler-reinforced vulcanized rubber[J]. Journal of Applied Polymer Science, 1965, 9(9): 2993-3009. DOI:10.1002/app.1965.070090906 |

| [3] |

Palmieri G, Sasso M, Chiappini G, et al. Mullins effect characterization of elastomers by multi-axial cyclic tests and optical experimental methods[J]. Mechanics of Materials, 2009, 41(9): 1059-1067. DOI:10.1016/j.mechmat.2009.05.002 |

| [4] |

Gracia L A, Pena E, Royo J M, et al. A comparison between pseudo-elastic and damage models for modeling the Mullins effect in industrial rubber components[J]. Mechanics Research Communications, 2011, 36(7): 769-776. |

| [5] |

Schlegel R, Wilkin D, Duan Y, et al. Stress softening of multigraft copolymers[J]. Polymer, 2009, 50(26): 6297-6304. DOI:10.1016/j.polymer.2009.10.026 |

| [6] |

Dorfmann A, Trimmer B A, Woods W A. A constitutive model for muscle properties in a soft-bodied arthropod[J]. Journal of Royal Society Interface, 2007, 4(13): 257-269. DOI:10.1098/rsif.2006.0163 |

| [7] |

Cheng M, Chen W. Mechanical behavior of bovine tendon with stress-softening and loading-rate effects[J]. Adv Theor Appl Mech, 2009, 2(2): 59-74. |

| [8] |

Canga M E, Becker E B, Ozupek S. Constitutive modeling of viscoelastic materials with damage-computational aspects[J]. Computer Methods in Applied Mechanics and Engineering, 2001, 190(15-17): 2207-2226. DOI:10.1016/S0045-7825(00)00231-0 |

| [9] |

Gratton M, Gontier C, Allah S R F, et al. Mechanical characterization of a viscoplastic material sensitive to hydrostatic pressure[J]. European Journal Mechanics-A/Solids, 2009, 28(5): 935-947. DOI:10.1016/j.euromechsol.2009.03.002 |

| [10] |

Le V D, Gratton M, Caliez M, et al. Experimental mechanical characterization of plastic-bonded explosive[J]. Journal of Materials Science, 2010, 45(21): 5802-5813. DOI:10.1007/s10853-010-4655-5 |

| [11] |

Yeom K S, Jeong S, Huh H, et al. New pseudo-elastic model for polymer-bonded explosive simulants considering the Mullins effect[J]. Journal of Composite Materials, 2013, 47(27): 3401-3411. DOI:10.1177/0021998312466118 |

| [12] |

Gray G T, Idar D J, Blumenthal W R, et al. High-and-low-strain rate compression properties of several energetic material composites as a function of strain rate and temperature[C]//Proceedings of the International Detonation Symposium, 11th, Snowmass, USA, 1998: 76-84.

|

| [13] |

Thompson D G, Idar D J, Gray G T, et al. Quasi-static and dynamic mechanical properties of new and virtually-aged PBX 9501 composites as a function of temperature and strain rate[C]//Proceeding of the Detonation Symposium, 12th, 2002: 363-368.

|

| [14] |

Kraus G, Childers C W, Rollmann K W. Stress softening in carbon black-reinforced vulcanizates-Strain rate and temperature effects[J]. Journal of Applied Polymer Science, 1966, 10(2): 229-244. DOI:10.1002/app.1966.070100205 |

| [15] |

Cheng M, Chen W. Experimental investigation of the stress-stretch behavior of EPDM rubber with loading rate effects[J]. International Journal of Solids and Structures, 2003, 40(18): 4749-4768. DOI:10.1016/S0020-7683(03)00182-3 |

| [16] |

Boyce M C, Socrate S, Llana P G. Constitutive model for the finite deformation stress-strain behacior of poly (ethylene terephthalate) above the glass transition[J]. Polymer, 2000, 41(6): 2183-2201. DOI:10.1016/S0032-3861(99)00406-1 |

| [17] |

Dorfmann A, Ogden R.W. A constitutive model for the Mullins effect with permanent set in particle-reinforced rubber[J]. International Journal of Solids and Structures, 2004, 41(7): 1855-1878. DOI:10.1016/j.ijsolstr.2003.11.014 |

| [18] |

Ogden R W, Roxburgh D G. A pseudo-elastic model for the mullins effect in filled rubber[J]. Proceedings of the Royal Society of London A, 1999, 455(1988): 2861-2877. DOI:10.1098/rspa.1999.0431 |

| [19] |

Beatty M F, Krishnaswamy S. A theory of stress-softening in incompressible isotropic materials[J]. Journal of the Mechanics and Physics of Solids, 2000, 48(9): 1931-1965. DOI:10.1016/S0022-5096(99)00085-X |

| [20] |

Boyce M C, Arruda E M. Constitutive models of rubber elasticity: A review[J]. Rubber Chemistry & Technology, 2000, 73(3): 504-523. |

The cyclic loading and unloading stress-strain curves of cast PBX in the quasi-static strain rate range of 10-4-10-2/s were obtained by a material testing machine. The constitutive behavior of PBX was analyzed by Dorfmann and Ogden′s model.