- Online First |

- Articles in press |

- Current Issue |

- Special Articles |

- Archive

-

YUE Chun-hui, LIU Bo, LI Man-man, WANG Feng, WEI Lun, WANG Qiong-lin

Online:July 25, 2024 DOI: 10.11943/CJEM2024173

Abstract:DA-propellant is a high-energy and low erosion propellant independently developed in China. It has the characteristics of high energy, low detonation temperature, good combustion cleanliness, and low smoke residue. This article summarizes the research on the synthesis and application azidenitroamine, formulation and performance of DA-propellant, manufacturing process, surface treatment, charge application, and testing methods. It also highlights that there are deficiencies in certain basic theoretical aspects and limited research on environmental adaptability of DA-propellant. Developing green, low-cost synthesis methods and mastering DIANP process amplification technology are effective ways to enhance competitiveness. It is also believed that the development of DA-propellant requires a combination of basic research and practical applications to promote the development of high-energy and low ablation characteristic materials in the industry.

-

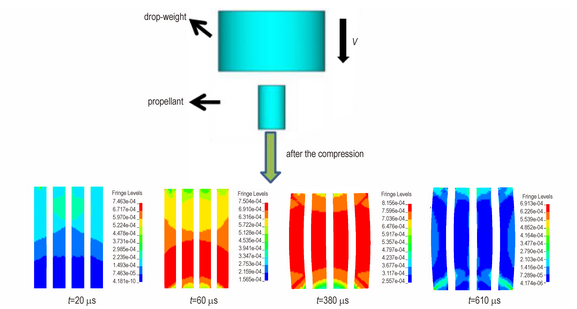

LIU Jia-hui, ZENG Cheng-cheng, ZHENG Sheng-jun, PANG Hai-yan, YANG Zhi-jian, NIE Fu-de

Online:July 24, 2024 DOI: 10.11943/CJEM2024013

Abstract:In order to study the influence of explosive crystal particle size on mechanical properties and interfacial enhancement of polymer bonded explosive (PBX), HMX-based PBXs were prepared by using four kinds of HMX with different particle sizes (160 µm,60 µm,25 µm and 150 nm) as main explosive. The fluorine resin and neutral polymeric bonding agent were used as binder and interface enhancement agent, respectively. The compressive stress-strain test and Brazilian test were performed to obtain the compressive and tensile mechanical properties of 8 types of PBXs at room temperature (20 ℃) and high temperature (60 ℃), respectively. The storage modulus and mechanical loss factor were obtained using the three-point bending mode of dynamic mechanical analysis. The cross-sections of PBXs were characterized by scanning electron microscopy. Results show that both the compressive and tensile mechanical strength of explosive increase with the decreasing of HMX particle size, in which the nano-HMX based PBX (PBX-nano) shows the highest strength. The compressive strength and tensile strength of PBX-nano are 61.3 MPa and 5.7 MPa, increasing by 73.1% and 63.5% from PBX-L, respectively. By adding the bonding agent, the compressive mechanical strength and tensile mechanical strength for all the PBXs are significantly improved, especially the PBX-nano. The tensile strength of PBX-nano-M at 20 ℃ and 60 ℃ are up to 10.4 MPa and 5.8 MPa, which are 82.6% and 101.4% higher than that of PBX-nano, respectively. When the average particle size of HMX decreases from 100 µm to 100 nm, the greater the fracture energy required for interface debonding/damage and even fracture of explosive, the greater the increase in tensile mechanical strength.

-

LIU Ze-hao, CHEN-Chong, LU Jia-xin, ZHANG Bo-bo, XIAO-Fei, LIU-Bo, LIANG Tai-xin

Online:July 01, 2024 DOI: 10.11943/CJEM2024109

Abstract:In order to study the corrosion inhibition characteristics and action mechanism of octaphenyl cage polysesquioxane (OPS) in the propellant, nitramine propellant samples with OPS content of 2%, 5%, 8% and control samples with no OPS were prepared. The ablation characteristics, combustion characteristics and energy properties of the propellant were studied using a semi-closed explosive device, a closed explosive device and an oxygen bomb calorimeter. The compatibility of OPS with nitramine propellant was studied by a differential scanning calorimeter (DSC). The microstructure, element distribution and product composition of the inner surface of the ablative tube were characterized by scanning electron microscopy (SEM) and energy dispersive spectroscopy (EDS). The results showed that OPS had good compatibility with nitramine propellant. When the OPS content was 5% and 8%, the ablation reduction rate was 23.9% and 36.0%, respectively. With the increase of OPS content, the ablation reduction rate gradually increases, while the energy and work ability of the propellant are reduced. The analysis of cracks, products and their distribution on the inner surface of the ablative tube showed that SiO2 generated by OPS at high temperature was uniformly distributed in the inner layer of the tube wall, forming a protective layer with excellent thermal resistance characteristics, and reducing the erosion and scouring effect of high temperature gas and solid particles on the tube wall.

-

WANG Wei-wen, CHEN Li-zhen, ZHANG Chao-yang, XIE Wei-yu

Online:June 26, 2024 DOI: 10.11943/CJEM2024111

Abstract:This study presents a method for rapidly estimating energy density based on the energy difference of chemical bonds, along with a technique for promptly evaluating cage structural stability by integrating Laplacian bond order and the bond dissociation energy of molecular fragments. By exhaustively constructing all nitrogen-rich frameworks derived from Noradamantane and its 435 nitro derivatives, the study applied the aforementioned computational methods to screen molecular structures with high energy density and stability. The reliability of the screening results was confirmed through quantum chemical energy calculations and transition state reaction barrier calculations. Two nitro compounds exhibiting both high energy density and structural stability were identified, with theoretical maximum values of detonation heat, detonation velocity, detonation pressure, and metal acceleration capability reaching 7.77 kJ·g-1, 10.1 km·s-1, 47 GPa, and 1.14 times the metal acceleration capability of HMX, respectively, and with structural decomposition reaction barriers ≥96 kJ·mol-1. The rapid screening method for energy density and stability of energetic molecules established in this study can provide theoretical guidance for the future design of high-energy stable energetic molecules.

-

SUN Xiao-qi, JIAO Fang-bao, LV Rui-bing, DUAN Xiao-hui, LI Hong-zhen

Online:June 17, 2024 DOI: 10.11943/CJEM2024095

Abstract:The octahedral cyclotrimethylenetrinitramine crystal (O-RDX) with an average particle size of 9.35 μm was prepared through the solvent-antisolvent method in the dimethylsulfoxide (DMSO) -ethylene glycol (EG) system using 1-ethyl-3-methylethimidazole acetate (EmimOAc) as an additive. The effects of crystallization parameters such as solvent system, solution concentration, crystallization temperature, additive and stirring speed on the growth behavior of RDX(cyclotrimethylenetrinitramine) crystals were systematically studied. It was observed that the main factor influencing the growth of RDX crystals was the supersaturation. With the gradual decrease of supersaturation, RDX crystals experienced the changes of rough growth, 2D growth and spiral growth, and the morphology of RDX crystals gradually evolved from dendritic to octahedral crystals. The results of analytical tests revealed that O-RDX crystals were in the α-form which was consistent with the raw RDX, showing high crystal density with few crystal internal defects and an increase of 5 ℃ in decomposition temperature. Moreover, compared to the raw RDX, the impact sensitivity and the friction sensitivity of O-RDX decreased by 60% and 50%, respectively. To further explore the formation mechanism of O-RDX, adhesion energy model and the molecular dynamics method were applied to simulate the crystal morphology of RDX in the presence of EmimOAc. The simulated results demonstrated that there were six main crystal faces of RDX: (1 1 1), (2 0 0), (1 0 2), (0 2 0), (2 1 0), and (0 2 1). The formation of the double-cone octahedral morphology originated from the uniform growth rates of the main crystal faces of RDX under the action of EmimOAc. The theoretical simulations generally agreed well with the experimental phenomena.

-

NIE Jian-xin, LIU Zheng, KAN Run-zhe, GUO Xue-yong, JIAO Qing-jie, YAN Shi

Online:June 17, 2024 DOI: 10.11943/CJEM2024117

Abstract:In order to study the combustion characteristics of aluminum powder in the detonation environment, based on the combustion model of aluminum powder in the detonation environment, the non-isothermal combustion model of aluminum powder in the detonation environment was established by comprehensively considering the effects of gas components of the detonation products and the temperature of the detonation environment system on the combustion and energy release process of aluminum powder. The non-isothermal combustion control equations of aluminum powder in the detonation environment, including the combustion process of aluminum powder, the gas components of the detonation products and the temperature of the detonation environment system, were proposed. And it was verified by laser induced breakdown spectroscopy experiments. The results show that the deviation between the calculated values of the non-isothermal combustion model control equation of aluminum powder and the experimental values of laser induced breakdown spectroscopy is within 12%, which verifies the accuracy of the theoretical model calculation. The laws of the influence of aluminum powder particle size and aluminum-oxygen ratio on the combustion characteristics of aluminum powder in explosives were obtained.

-

LI Wen-jia, CHAI Ya-ming, FANG Song-hang, WANG Bin-bin, DING Ya-jun, XIAO Zhong-liang, ZHOU Jie

Online:June 11, 2024 DOI: 10.11943/CJEM2024102

Abstract:Three cyclodextrin metal-organic framework (CD-MOF) materials were successfully synthesized using the vapor-diffusion method. The structures were analyzed via single-crystal X-ray diffraction. As potential flame suppressants, the three CD-MOFs exhibit lower thermal decomposition temperatures (250-300 ℃) than traditional potassium nitrate (722.0 ℃), allowing for potassium ion to release more easily. The good physical dispersibility and chemical compatibility within nitrocellulose (NC) are also demonstrated. Additionally, the NC containing CD-MOF produces fewer flammable and harmful gases (CO, NO, NO2, and N2O) during thermal decomposition. The single base propellant containing γ-CD-MOF shows the smallest flame area during combustion (119.6 mm2). In comparison, the single base propellant containing β-CD-MOF exhibits the lowest standard deviation in the flame area (8.4 mm2), indicating more consistent flame suppression performance. In contrast, the single base propellant containing KNO? displays the largest flame area (392.7 mm2).

-

YOU Jia-jun, WANG Bing, XIONG Ying, WANG Jian

Online:June 04, 2024 DOI: 10.11943/CJEM2024092

Abstract:The pilot-scale energetic material wastewater is a kind of wastewater which is extremely difficult to degrade, containing high concentrations of various nitrogen-containing compounds, such as ammonia nitrogen (NH3-N), nitrite (NO2-), nitrate (NO3-), and other organic pollutants . To realize the efficient and directional removal of these nitrogen-containing compounds, boron-doped diamond (BDD) electrodes were prepared by the hot-filament chemical vapor deposition (HFCVD) method and utilized to degrade the wastewater. The effects of electrolyte composition and concentration, modified electrode type, and electrolysis device structure on the degradation efficiency were investigated. It demonstrated that adding 0.1 M sodium chloride (NaCl) electrolyte to energetic material wastewater could improve the selectivity of NH3-N direct conversion to nitrogen (N2). Using Cu/BDD and Ni/BDD cathodes accelerate the conversion process of high-valent nitrogen to NH3-N. Under the dual electrolysis cell structure system, employing Cu/BDD and Ni/BDD electrodes as anodes improve the degradation rate of NH3-N conversion to N2. Therefore, the approach utilizes metal-modified BDD electrodes as anodes, is expected to be a highly effective method in the rapid and selective degradation of energy material wastewater, especially when using 0.1 M NaCl as electrolyte.

-

LIU Rui, YANG Dan-feng, ZHANG Yun-long, NIE Hong-qi, YAN Qi-long

Online:June 04, 2024 DOI: 10.11943/CJEM2024062

Abstract:In order to improve the ignition and combustion performance of boron powder, four kinds of micro- and nano B-Fe-Bi2O3@AP/PVDF composite were prepared by high-energy ball milling combined with spray drying method. According to their high calorific value and high combustion efficiency, four composite were named as μBHHc, μBHCe, nBHHc, and nBHCe. Their morphology, thermal reactivity, ignition delay time, mass burning rate and condensed phase combustion products were characterized and analyzed. The results show that the maximum calorific value of μBHHc and μBHCe composite in argon is 9.7 kJ·g-1, and the maximum combustion efficiency in argon is 66.2 %. The maximum calorific value in oxygen is 14.6 kJ·g-1, the maximum combustion efficiency is in oxygen 93.3%, and the oxidation peak temperature is between 750 ℃ and 760 ℃. The maximum calorific value of nBHHc and nBHCe composite in argon is 9.9 kJ·g-1, and the maximum combustion efficiency is in argon 68.9%. The maximum calorific value in oxygen is 14.8 kJ·g-1, the maximum combustion efficiency in oxygen is 97.2%, and the oxidation peak temperature is between 595 ℃ and 600 ℃. The highest combustion temperature of all kinds of composite is between 1954 ℃ and 2011 ℃. The ignition delay time of nBHHc composite is the shortest (26 ms), while the mass burning rate is the highest (1.84 g·s-1). The μBHCe composite has the longest ignition delay time (39 ms) and the lowest mass burning rate (0.80 g·s-1). The condensed phase combustion products of various composites are mainly composed of B2O3, B4C and a small amount of incompletely burned boron. The morphology of condensed phase combustion products includes 5-10 μm spheres and 10-20 μm flakes.

-

LI Si-heng, QU Wen-gang, ZHAO Feng-qi, JIANG Yi-fan, ZHANG Zhen, ZHANG Ming, ZHANG Jian-kan, LIU He-xin

Online:June 03, 2024 DOI: 10.11943/CJEM2024037

Abstract:Ammonium perchlorate (AP) is an important oxidant in solid propellants, and its thermal decomposition performance directly affects the combustion characteristics of solid propellants. The use of combustion catalysts can lower the decomposition temperature and increase the decomposition rate of AP. Different methods for microstructure control of nano-combustion catalysts for AP thermal decomposition were studied and summarized. The effects of microstructure control methods such as crystal planes, defects, and composite interfaces on the catalytic activity and catalytic mechanism of combustion catalysts for AP thermal decomposition reaction were analyzed. Besides, the characteristics of catalysts that can achieve optimal catalytic performance were explored. The results indicate that the catalytic activity of nanometal oxide combustion catalysts can be improved by adjusting the exposed crystal faces, element doping and constructing a composite interface structure. Among them, transition metal oxide nano-catalysts can enhance catalytic activity by exposing designated crystal planes, and element doping enhances catalytic activity by generating defects, while constructing a composite interface structure utilizes interface effects to regulate the activity of catalytic sites, thereby enhancing catalytic activity. Transition metal oxide nano-catalysts showed good catalytic activity in improving the thermal decomposition performance of AP.

-

CHEN Chun-lin, ZHAO Jian-chun, TU Wen-wen, XIONG Peng, YANG Qin, YANG Qi, ZHANG Jun

Online:June 03, 2024 DOI: 10.11943/CJEM2024070

Abstract:To adapt to the operational requirements of the wide temperature range environment-for the single-based propellant, this work investigated the modification effects of temperature coefficient of propellant through physical structure modification, insensitive technology, and surface modification methods. Here, the prepared propellant was evaluated by the internal ballistic performance test. The low temperature velocity temperature coefficient and high temperature chamber pressure temperature coefficient could be controlled below 5% and 10%, respectively when the propellant was modified with 5% pore extender, a particle size of energetic solid material of 55 μm, the insensitive agent MA, and surface sensibilization modification. The modification mechanism for the propellant towards these methods is attributed to that the pores, irregular bulge, open interface, and zipper hole section structure are formed. Hence, at the lower temperature-condition, because of the porous layer and PMA of the propellant becoming brittle, the impact resistance being weakened, the fracture tendency of the pores and the interface being increased, the initial burning surface of the propellant was increased at low temperature. At the lower temperature condition, because of the closed hole phenomenon of the propellant blocked (closed) hole layer being intensified, insensitive agent being expanded and squeezed into the hole, the impact resistance being enhanced, the fracture tendency of the pore and the interface being reduced, the initial burning surface of the propellant was reduced under high temperature conditions. Through the compensation of the burning rate, the aim of adjusting the temperature coefficient of the propellant is achieved.

-

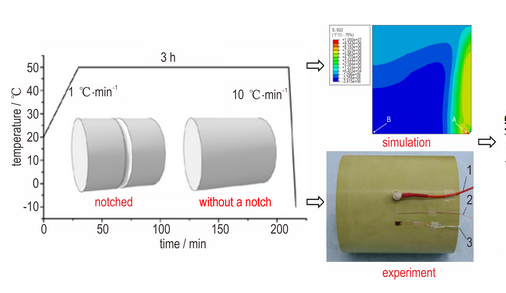

XU Li-ji, BAI Zhi-ling, DUAN Zhuo-ping, HUANG Feng-lei

Online:May 31, 2024 DOI: 10.11943/CJEM2024072

Abstract:As an important thermodynamic parameter of explosives, thermal conductivity significantly affects the ignition response characteristics of explosive charge. In order to quickly and effectively obtain the thermal conductivity of explosives without tests, an axisymmetric heat conduction theoretical model of typical cylindrical charge structure is established, and its steady-state analytical solution is derived. Also, a method for calculating the thermal conductivity of explosives is proposed based on the slow cook-off experimental data. The thermal conductivity of a new type of insensitive explosive, GOL-1(HMX/Al/AP/Binder), is determined. The numerical simulation results of the ignition response of small-size charge structure under typical cook-off conditions shows that the calculated results of the charge center temperature-time curves at different heating rates are basically consistent with the experimental results, and the deviations of ignition temperature at charge center and ignition time between the calculated and experimental results are 2.27% and 1.12% at most, which indicates the effectiveness of the thermal conductivity of the GOL-1 and the feasibility of the numerical simulation method. The established calculation method reveals the thermal conductivity characteristics and rules based on the temperature-time curves of slow cook-off experiments, which is more suitable for calculating the thermal conductivity of explosives compared with volume-weighted method and string or parallel heat conduction model. In the absence of experimental data for determining the thermal conductivity of new explosives, this method is an effective determination method, providing a basic parameter for the design and evaluation of thermal safety of ammunition and promoting the development of digital design and quantitative evaluation of safe ammunition.

-

LIANG Hao, WANG Duo-liang, SUN Qian, Ding Ya-jun, Li Shi-ying, Li Hong-wei, Xiao zhong-liang

Online:May 30, 2024 DOI: 10.11943/CJEM2024075

Abstract:Nitro gradiently distributed propellant (NGDP), as a new type of propellant, has the characteristics of high oxygen balance, less harmful for use, and anti-migration. To analyze the thermal hazard of denitration reaction in the preparation process of NGDP, the exothermic process during the denitration reaction and the thermal decomposition behavior of the material, the reaction was measured by reaction calorimeter (RC1mx), differential scanning calorimeter (DSC) and accelerated adiabatic calorimeter (ARC). The results showed that the exothermic amount of the denitration reaction was 61.46 kJ, and the adiabatic temperature rise (ΔTad) of the reaction system calculated from this was 58.28 ℃. In the DSC test, the denitration treatment increased the decomposition temperature of the double base propellant from 191.33 ℃ to 194.16 ℃. Based on the ARC test data of the post-reaction system, the relationship between the Time to Maximum Rate (TMRad) and the temperature was calculated. When the adiabatic induction period is 24 hours, the corresponding TD24 is 137.2 ℃. The TD24, maximum technical temperature (MTT), and maximum temperature of the synthesis reaction (MTSR) of the reaction are 137.2 ℃, 108 ℃, and 128.52 ℃, which means that the system had the risk of spraying in case of cooling failure. However, the risk of triggering the secondary decomposition reaction was low.

-

Liu Qiong, Liu Lu, Xi Yuan-wei, GAO Zhi-zhong, Du Ping

Online:May 28, 2024 DOI: 10.11943/CJEM2024079

Abstract:To reduce the erosion of R2 high-energy propellant, a new composite erosion inhibitor based on silicon/modified nano TiO2/paraffin was designed and prepared. The erosion-reducing performance of the new type of composite erosion inhibitor was studied by a semi-closed bomb test with the standard erosion inhibitor as the reference material. The erosion inhibition mechanism of new composite erosion inhibitor was studied by scanning electron microscope-energy dispersive spectrum, and its effect on the static combustion property of propellant was investigated using a closed bomb. The results show that the new composite erosion inhibitor has a significant effect on reducing erosion. The erosion inhibition rate can reach 34.24% when the addition of erosion inhibitor is 5%. Decamethylcyclopentasiloxane (D5) in the erosion inhibitor is decomposed at high temperature, and the silicon oxide nanoparticles produced by the decomposition can effectively block the carburization reaction by adhering to the inner wall of the erosion tube. Since R2 propellant added with new composite erosion inhibitor has higher combustion progressivity, the energy is released at the later stage of combustion which is beneficial to reduce the erosion. The new composite erosion inhibitor has great applied potential.

-

PENG Yue, ZHANG Lei, XIE Ming-wei, MA Hong-liang, YUAN Xiao-xia

Online:May 24, 2024 DOI: 10.11943/CJEM2024021

Abstract:For accurately describe the thermodynamic relationship of detonation products under high temperature and pressure, so as to achieve reliable prediction of the detonation performance of CHNO elemental/mixed explosives and energetic metal salts. In this work, a new equation of state (EOS): Virial-Peng-Long (VPL) for gaseous detonation products, was established based on the theoretical calculation of the 2-5th order virial coefficients of Exp-6 potential within a wide dimensionless temperature range. At the same time, a new EOS for condensed metal products: Wu-Chen-Peng (WCP) EOS, was established by introducing a more accurate“cold pressing” term, and a “lattice vibration” term which considered the changes in the thermal motion of metals under high pressure. Then, the VPL EOS was applied to calculate the detonation parameters of some typical CHNO elemental/mixed explosives, and the detonation CJ parameters and driving capacity of some typical energetic metal salts were evaluated using VPL and WCP. By comparing with experimental values, it is shown that the prediction deviation of detonation velocity of pentaerythritol tetranitrate (PETN) is within ± 2.1%, with a maximum of about 2.5%; The absolute prediction error of the stable speed of copper cylinder driven by RHT-901 is less than 1%. VPL EOS and WCP EOS in this work can accurately evaluate the detonation performance of energetic metal salts. The relative error of detonation CJ parameters calculation for lead azide is within ±4%, and the absolute value of relative error in predicting the speed of copper azide driven flyer is within 1%.

-

WANG Ze-kun, CHEN Li, CAO Ming-jin, TANG Bai-jian

Online:May 24, 2024 DOI: 10.11943/CJEM2024054

Abstract:To enhance the modeling and computational efficiency of numerical simulations for penetration resistance in ultra-high molecular weight polyethylene fiber (UHMWPE) laminates, an equivalent mechanical model of UHMWPE laminates was established based on the theory of three-dimensional equivalent elastic constants, and a three-dimensional equivalent rapid simulation method suitable for predicting the penetration resistance of fiber composite laminates was developed. As verified by the UHMWPE laminates" penetration test data, the equivalent method can accurately simulate and predict the staged penetration characteristics of laminates by taking into account the influence of the fiber lay-up on the mechanical properties of the laminates, and the average errors for the ballistic performance of 9.1-60.0 mm laminates are less than 10%. The method bypasses the need for detailed modeling of fiber bundles and matrices, as required in mesoscopic scale numerical simulations, and eliminates the necessity of specifying individual fiber/resin ply orientations and inserting numerous bonding elements, as in quasi-mesoscopic scale simulations.

-

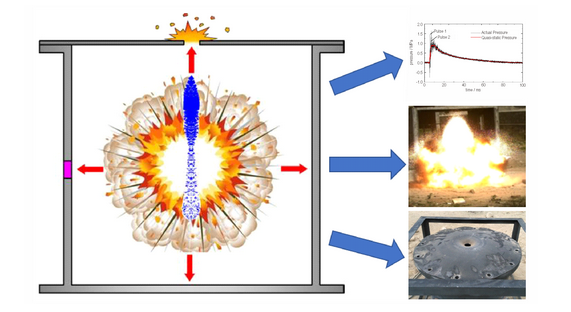

YUAN Mao-bo, JIN Jian-wei, QU Yong-jie, LIU Ji-hua, XUE Jun, HE Chang-hui, ZHAO Hong-li

Online:May 23, 2024 DOI: 10.11943/CJEM2024036

Abstract:A semi-closed bomb experiment was designed to construct a system for evaluating the erosion performance of propellant according to actual requirements. A transient numerical simulation model was established based on the geometric dimensions of the erosion tube and the measured p-t curve. The relationship between the transient erosion rate model parameters and the total mass loss of erosion tube was established through the space-time distribution of wall temperature of the erosion tube. Based on the mass loss of the semi-closed bomb experiment, the parameters of erosion reaction were optimized by particle swarm algorithm. The results showed that both the temperature of the interface between the propellant gas and the erosion tube wall and the growth rate of melting depth decreased with the increase of erosion time. The 45# steel and double base powder (Shuang-fang 3) were selected as the material sample and propellant sample. The optimized pre-factor and apparent activation energy values were 0.3403 s-1 and 134.6 kJ?mol-1, respectively. At this time, the value of loss function was only 3.0×10-6. Thus, the transient erosion rate model is a promising tool to evaluate the erosion status of the barrel weapon.

-

LIU Wei, GOU Xiao-dong, GUO Xiao-zhuang, YANG Cai

Online:May 22, 2024 DOI: 10.11943/CJEM2024027

Abstract:Two new explosives, C8H24N4(ClO4)4 and C8H24N4(NO3)4?2H2O, were prepared from 1,4,7,10-tetranitrocyclododecane by salt formation with nitric acid and perchloric acid respectively, which are expected to be used as emergency reserve materials of weapons in emergency wartime. The structures, thermal properties, and detonation performances of the target products were studied through single crystal X-ray diffraction, infrared spectroscopy, elemental analysis, differential thermal analysis, thermogravimetric analysis, and EXPLO 5.0 program. The results indicate that C8H24N4(ClO4)4 crystallizes in the orthogonal crystal system, Pcc2 space group with a crystal density 1.968 g?cm-3. The crystal of C8H24N4(NO3)4?2H2O is a dihydrate with a crystal density of 1.642 g?cm-3, which belongs to the monoclinic crystal system P21/n space group. The thermal decomposition peak temperatures of C8H24N4(NO3)4?2H2O and C8H24N4(ClO4)4 are 293.2 ℃ and 284.1 ℃, and activation energies are 131.76 kJ·mol-1 and 195.18 kJ·mol-1, respectively. Compounds C8H24N4(NO3)4?2H2O and C8H24N4(ClO4)4 exhibit excellent detonation properties, showing very promising performance values (C8H24N4(NO3)4?2H2O, V=8058 m?s-1, P=24.0 GPa; C8H24N4(ClO4)4, V=8680 m?s-1, P=36.2 GPa). Moreover, the impact sensitivities of C8H24N4(NO3)4?2H2O and C8H24N4(ClO4)4 are 36 J and 33 J, respectively, and their friction sensitivities are higher than 360 N.

-

ZHAO Ya-qi, YANG Sha, CAO Wei, GUO Wei, SONG Qing-guan, DUAN Ying-liang, HUANG Bing, HAN Yong

Online:May 15, 2024 DOI: 10.11943/CJEM2024052

Abstract:To obtain the ignition and growth model parameters of HNS-Ⅳ based polymer bonded explosive (PBX) under shock initiation, the shock wave loading method from explosive plane wave lens was used. The shock waves were attenuated by attenuators and impacted with tested explosives, and the interface particle velocity profiles between tested explosives and LiF (lithium fluoride) windows were measured by photonic Doppler velocimetry. Several explosive pellets with varying thicknesses could be mounted to the attenuator in one shot, by adjusting the thickness of attenuator to change the input pressure, the growth process of interface particle velocity was obtained. Meanwhile, the unreacted shock adiabatic curve of tested explosive was measured by the reverse-impact method, and the cylinder expansion velocity history was acquired by 10 mm diameter cylinder test. Then, the JWL (Jones-Wilkins-Lee) equation of state (EOS) parameters of unreacted explosives and detonation products were fitted with experimental results by genetic algorithm. Finally, the interface particle velocity histories between explosives with varying thicknesses and LiF windows were fitted with the ignition and growth model. The results show that the fitting correlation coefficients of EOS parameter curves for unreacted explosives and detonation products are high enough, and the obtained ignition and growth model parameters well simulate shock initiation experimental results, which can meet the requirement of initiation train design.

-

GUO Zhi-gang, LI Man-man, WANG Feng, YU Hui-fang, WEI Lun, WANG Qiong-lin

Online:May 15, 2024 DOI: 10.11943/CJEM2024069

Abstract:In order to investigate the application of the fuzzy comprehensive evaluation model in the modification evaluation of high energy nitramine gun propellant, the triamino trinitrobenzene (TATB) coated and polyester (NA) coated gun propellant were prepared by coating technology using TATB and NA as the burning rate reduction materials, and their bulk densities, burning rates, explosion heats, propellant burning progressivities and interior ballistic performances were compared. Moreover, the analytic hierarchy process (AHP) was adopted to quantify the influence of TATB and NA on the basic characteristics and the combustion performances above. It was found that, the fuzzy comprehensive evaluation can be established between the basic characteristics and combustion performances of propellants. For the better overall combustion performance, the weight of burning rate is equal to 0.82, which is the highest; the weights of explosion heat and bulk density are equal to 0.11 and 0.07, respectively. In the case of small difference in bulk density, even though the energy loss caused by NA coating is greater than that of TATB coating, the decrease of burning rate by NA coating would be larger and the propellant coated with NA has the better performance than the propellant coated with TATB, and the two are significantly better than that of blank propellant

-

HONG Yin, LIU Kan, WU Yi, WU Yan-qing, YANG Xiu-feng

Online:April 26, 2024 DOI: 10.11943/CJEM2024043

Abstract:The planetary motion of impeller in the vertical mixer can effectively promote the dispersed circulation and homogeneous distribution of different material components, which has been employed in the preparation procedure of solid propellant slurry. However, the mixer involves complex interfaces and motions that it is difficult to study the mixing mechanism and rheological property of slurries by traditional methods. Based on the smoothed particle hydrodynamics (SPH), the continuum was discretized into the conserved particles with physical quantities for simulating the interaction between the propellant slurry and blades under laminar flow. A meshless method for the mixing process of propellant slurries in non?Newtonian fluid state was developed by combining the Herschel?Bulkley (HB) constitutive model. The numerical simulations were compared with the experiments to verify the accuracy of the proposed model. The correlations of the blade motion parameters and power consumption were explored. The effects of geometric configurations and rotation modes on the mixing uniformity of slurries and the torque loads of impellers were analyzed. Research findings indicate that the simulation and literature experiment results have a good agreement that the average relative error between them is around 4.98% in the non?Newtonian fluid with shear rate index n = 0.47. The mixing uniformity index of planetary impellers increased by 8.9% and 7.3% respectively than those of central and eccentric impellers after stirring for 2.65 s. The maximum amplification in torque can reach 38.4% within the revolution radius range of 0.11Dw-0.23Dw at Reynolds number Re = 1.

-

REN Hai-chao, JIA Xian-zhen, LIU Rui-peng, WANG Hao, SUN Xiao-yu, ZHANG Zeng-ming, TAO Jun, WANG Xiao-feng

Online:April 26, 2024 DOI: 10.11943/CJEM2023271

Abstract:To gain a comprehensive understanding of the properties changes of TNT crystals under strong magnetic field radiation, the morphological changes, the lattice constants and the thermal decomposition characteristic were explored using the scanning electron microscope, X-ray diffraction, Raman spectroscopy and differential scanning calorimeter (DSC), respectively. Moreover, the variations of lattice constants, molecules distributions, mechanical properties and theoretical impact sensitivity of TNT under magnetic field radiation were investigated by molecular dynamics simulations. The experimental results, with the application of 6 T magnetic field, showed that the microscopic morphology was changed from the scale-needle structure to the irregular block structure, and the exothermic peak temperature of thermal decomposition was increased from 289.6 ℃ to 304.1 ℃. However, the crystal phase structure and lattice constants of the TNT remained unchanged. Furthermore, theoretical investigations indicated that the TNT lattice constant not affected by magnetic field radiation, but the magnetic field did change the molecules distribution in the TNT crystal. The 8 T magnetic field radiation significantly improved the ductility of TNT. However, it simultaneously increased the impact sensitivity of TNT by comparing the ratio for the longest trigger bonds.

-

ZHONG Su-yang, LIAO Shen-fei, HU Qiu-shi, LI Tao, FU Hua

Online:April 25, 2024 DOI: 10.11943/CJEM2023245

Abstract:In order to study the potential mechanism of unexpected ignition of confined charge in the process of penetrating multi-layer target, by integrating the designs of multi-layer nested strikers and bidirectional limited structure, a nonlinear amplification experimental method of confined charges under continuous multiple impacts loading was established. The effectiveness of the experimental method, and the intrinsic mechanism of nonlinear response amplification were analyzed. The influence of nonlinear response of charges under multiple impacts loading on ignition behaviors was studied. The results show that the experimental method can implement multiple impacts loading with sub-millisecond pulse width, and 100 MPa-scale peak stress value. When the characterized frequency of loading is close to the intrinsic frequency of confined charges, structural nonlinear response amplification emerges, and the stress amplitude increases gradually. For the same striker velocity and mass, while varying frequency of loading, the PBX-3 charges could be ignited if structural nonlinear response is amplified and could not be ignited if structural nonlinear response is not amplified. It is found that the structural nonlinear response amplification effect is an important factor leading to charge ignition.

-

LI Sheng-wei, XU Dong, SUN Sen, ZHOU Jin-qiang, WU Cheng-cheng, GUO Xue-yong

Online:April 25, 2024 DOI: 10.11943/CJEM2024049

Abstract:In order to solve the problems of low density and effective oxygen content of the existing oxidant NH4ClO4 (AP) for mixed explosives, the oxidant KClO4 (KP) with higher density and oxygen content was compounded with AP, and the optimal ratio of AP/KP composite oxidant was determined by Molecular Dynamics. The novel AP/KP composite oxidant with high density and high oxygen release was prepared by physical mixing and solvent evaporation method, respectively, and its elemental composition, morphology, structure, composition and thermal properties were characterized by inductively coupled plasma spectrum generator (ICP), scanning electron microscope (SEM), X-ray powder diffractometer (XRD) and thermal analyzer (DSC-TG). The results show that element and particle size distribution of the AP/KP composite oxidant prepared by solvent evaporation method is reasonable and uniform. The crystal form has not changed, and the crystal form is relatively complete, as proved by XRD. The thermal decomposition peak temperature of AP and KP was decreased by 11.25 ℃ and 13.87 ℃, respectively, which was more conducive to the thermal decomposition process. In addition, the composite oxidants prepared by physical mixing and solvent evaporation method were introduced into typical metal combustible agent Al powder, the ignition and combustion properties of samples prepared by different methods with Al powder were compared and studied. The results show that when the AP/KP composite oxidant prepared by solvent evaporation was mixed with Al powder, the combustion calorific value reached 12.228 MJ·kg-1, and the pressurization rate reached 5.21 MPa·s-1. The laser ignition test shows that the shortcomings of slow AP combustion reaction rate and difficult KP ignition were greatly improved.

-

REN Jia-tong, CUI Peng-teng, ZHANG Heng, DING Feng, GAO Yu-chen, YANG Wei-tao

Online:April 18, 2024 DOI: 10.11943/CJEM2024076

Abstract:In order to explore the application prospect of a novel azido plasticizer 1,5-diazide-3-oxapentane (AZDEGDN) in gun propellant formulation, a semi-solvent method was adopted to prepare double- and triple-base gun propellants using AZDEGDN as the plasticizer, and the morphology, density as well as static combustion performance at different temperatures of AZDEGDN-containing propellants were studied. Results show that the AZDEGDN-containing double-base propellant (ADG-2) and triple-base propellant (ADG-3) without obvious defects in appearance can be prepared by semi-solvent extrusion process. SEM test shows that solid additives hexogen (RDX) and nitroguanidine (NGu) are uniformly distributed within ADG-3 propellant. The density of ADG-2 is 1.44 g·cm-3 and ADG-3 is 1.52 g·cm-3, both close to their theoretical density, indicating that the internal structures of AZDEGDN-containing propellants are relatively dense. The closed vessel tests demonstrate that the static combustion performances of both ADG-2 and ADG-3 propellants at room temperature (20 ℃) are stable. The burning rates increase evenly with the increase of pressure, without obvious turning phenomenon in burning rate-pressure curves (u-p curves). The maximum combustion pressure of ADG-2 and ADG-3 propellants is 237.71 MPa and 263.80 MPa, and the burning rate pressure index is 0.9098 and 0.9754, respectively. The addition of RDX and NGu results in an increase of 15.5% and 10.9% in the burning rate pressure index of AZDEGDN-containing propellants in the low pressure range (50-100 MPa) and medium pressure range (100-150 MPa) respectively, while the burning rate pressure index in the high pressure range decreases by 4.2%. At high temperature (50 ℃) and low temperature (-40 ℃), ADG-3 propellant can still keep stable combustion. The maximum combustion pressure changes from 263.80 MPa in room temperature to 265.92 MPa and 261.13 MPa, respectively. Besides, the combustion time changes from 14.70 ms to 13.52 ms and 16.40 ms respectively, and the burning rate pressure index changes from 0.9754 to 0.9464 and 0.9938 respectively. It is concluded that AZDEGDN-containing gun propellant is simple and mature in preparation method, dense and defect-free in structure, and also stable in static combustion performance, which is expected to become a kind of novel low-ablation gun propellant.

-

CAO Ke-lei, FU Qiao-feng, Zhang Jian-wei, HUANG Jin-lin, ZHAO Yu

Online:April 15, 2024 DOI: 10.11943/CJEM2024032

Abstract:In order to explore the underwater anti-explosion protection effect of different corrugated steel-concrete composite structures, the finite element-smoothed particle hydrodynamics (FEM-SPH) coupling algorithm was used to establish an underwater multi-media coupling explosion model. Different corrugated steel-concrete slab composite structure protection schemes were designed to explore the underwater wave cutting and energy absorption effects of different composite structure protection layers, including 3, 6, 9, 12 mm thick corrugated steel composite structure, 30°, 45°, 60°, 75° corrugated steel composite structure and 10, 30, 50, 70 mm wave height corrugated steel composite structure. The energy consumption sharing rate was proposed to evaluate the protection effect of the composite structure. The results show that simulation results of the front and back explosion surfaces of the concrete slab are in good agreement with experimental results, which verifies the simulation process of underwater contact explosion. Under different composite structure protection schemes, the peak pressure of the composite structure with 12 mm thick corrugated steel, the composite structure with 75° corrugated steel and the composite structure with 70 mm wave height is 63.2%, 60% and 57.9% lower than that of the unprotected scheme, respectively. The maximum protection rates are 63.2%, 60.0% and 57.9%, respectively, and the energy consumption sharing rates are 69.48%, 66.26% and 63.51%, respectively. The energy absorption effect and protection effect of the optimal composite structure with 12 mm thickness, 75° angleand 70 mm wave height are significantly better than those of the composite structure under the influence of single factor. The research results can provide a theoretical basis for the application of different corrugated steel-concrete composite structures in the field of underwater anti-explosion protection.

-

ZHANG Ye, WANG Xin-yu, XU Wen-yu, WANG Zai-cheng, JIANG Chun-lan

Online:March 28, 2024 DOI: 10.11943/CJEM2024010

Abstract:To investigate the cook-off response characteristics of JEO explosive (NTO/HMX/additives), an experimental system for multi-point temperature and pressure measurements during the cook-off process of explosive was devised. The cook-off experiments of JEO explosive were conducted at two different heating rates of 5 ℃·min-1 and 2 ℃·min-1 to obtain the ignition time, ignition temperature, temperature history at different positions within the explosive, and pressure evolution inside the device. The effect of heating rates on temperature and pressure variations and reaction intensity during the cook-off process of JEO explosive was analyzed. Furthermore, based on the experimental research, a multiphase flow species transport model for explosive cook-off was adopted considering the influence of pressures on the thermal decomposition reaction of explosive, and numerical simulations were conducted to investigate the thermal decomposition process of JEO explosive under different heating rates using Fluent software. The results indicate that the thermal decomposition reaction of JEO explosive proceeds slowly before phase transition, while it accelerates significantly afterwards, leading to a rapid increase in temperature and an exponential growth in pressure until ignition. The ignition temperature of JEO explosive is approximately 220 ℃, and its response level is deflagration under the constraint conditions of this experiment, demonstrating excellent thermal safety. As the heating rate decreases, the ignition time of JEO explosive prolongs, and the ignition location shifts from the edge of the charge towards the center, resulting in an increased intensity of the reaction. During the thermal decomposition process before ignition, only a small portion of the explosive undergoes reaction, with the majority of the reaction occurring during the combustion stage after ignition.

-

LIU Dan, WANG Jun-ru, ZHAO Xu, YANG Zhi-jian

Online:March 26, 2024 DOI: 10.11943/CJEM2023269

Abstract:The morphology and structure of energetic materials have significant impact on their various properties. In order to improve the inherent performance of existing energetic materials and meet the different application requirements of weapon, the assembly of energetic materials is an effective technology. Based on the relevant works of domestic and foreign scholars, the current methods of energetic materials assembly and the effects on performances were summarized from two perspectives: the directly affecting the structure of single-component energetic materials through assembly and regulating their performance, and the assembly components and composite structure of multi-component composite energetic materials synergistically regulating the performance. The enlightenment of other functional materials assembly for energetic material was elaborated. Currently, the assembly of single-component energetic materials can achieve new crystal morphology, while multi-component assembly can compensate for the inadequacy of available performance control, and achieve synergistic improvement of energy and safety performance. However, the development of energetic material assembly still faces problems such as monotonous assembly methods, difficult process control, unclear assembly mechanisms, and insufficient research on multi-components. Future research may focus on three perspectives: the improvement of crystal assembly theory for energetic materials, the development of mesoscopic characterization techniques, and the exploration of new assembly technologies.

-

CHENG Bing, WANG Hai-bo, CHENG Yang-fan, WANG Quan, LV Nao, HAN Ti-fei

Online:March 12, 2024 DOI: 10.11943/CJEM2023266

Abstract:To study the transfer characteristics of explosion energy released by the charge confined to tubes of different materials with lateral annular slits, explosion experiments were conducted involving charges with or without confinement to tubes of four materials. The high speed schlieren photographic system and shock wave overpressure monitoring system were employed to capture the propagation process of shock wave and obtain the distribution law of overpressure respectively, so that the explosion energy transfer law for the charges confined to tubes with lateral annular slits and the influence of tube material on its energy transfer characteristics were analyzed. The results showed that after the explosion of the charge confined to tubes with lateral annular slit, both the detonation product and shock waves firstly propagated outward towards the direction with slit, but the propagation towards the opposite direction is relatively delayed. Compared with the symmetric distribution of overpressure generated by a conventional cylindrical charge, the lateral annular slits in tubes could increase the overpressure in the direction with slit, but decrease that in the opposite direction. The asymmetric distribution of overpressure proved that the charge confined to tubes with lateral annular slits induced Munroe Effect in the slit direction. The hierarchy of Munroe Effect caused by lateral annular slits presented by materials: stainless steel (SS) > polyvinyl chloride (PVC) > fiber reinforced plastic (FRP) > plexiglass (PMMA).

-

WU Rui, XIAO Yi-jie, LI Qiang, YUAN Mao-bo, LIU Bo, ZHANG Yu-cheng

Online:March 07, 2024 DOI: 10.11943/CJEM2024033

Abstract:In order to investigate the thermal erosion characteristics and variation law of triple base propellant, various kinds of gun propellants with different components content were prepared. The erosion characteristics were determined through simulated test in a semi-closed bomb. The analysis reveals the impact of energy component and plasticizer content on gun propellant explosion temperature, and the impact of explosion temperature on erosion characteristics. The results indicate that changes in the explosion temperature of gun propellant, attributed to variations in cyclotrimetheylenetrinitramine (RDX), nitroguanidine (NQ) and dioctyl phthalate (DOP) content, significantly affect erosion characteristics. An increase of 1% in RDX content results in an increase in explosion temperature by 0.59% and an increase in erosion rate by 1.23%. Compared with the absence of RDX, the erosion rate of 2% RDX-containing propellant increase 23.38%. Notably, an increase of 1% in NQ content reduces the explosion temperature by 0.23% and the erosion rate by 0.56%. An increase of 1% in DOP content reduces the explosion temperature by 2.99% and the erosion rate by 7.01%. For the triple base propellants within the range of explosion temperature from 2600-3100 K, an exponential relationship between the rate of erosion mass and explosion temperature is established, and characteristic coefficients of RDX, NQ, DOP system is given respectively, which is 0.106, 0.101, 0.163.

-

WEN Yi-meng, MAO Jun-qing, MA Song-yu-chen, DI Yang, LIU Tao, LIU Jie

Online:January 25, 2024 DOI: 10.11943/CJEM2023200

Abstract:Due to contacts with additives or changes of environmental conditions (temperature or pressure), the polymorphism hexanitrohexaazaisowurtzitane (CL-20) is easy to transform into mixed crystal form in propellant system, which leads to structural damage and performance degradation of the propellant. In order to hinder the contact between the solvent and CL-20, then inhibit the crystal transformation of CL-20, the polyphenol amine (PCHA) film was prepared based on the oxidative self-polymerization of hexamethylenediamine (HMDA) and catechol (CCh). The surface of CL-20 crystal was modified by water suspension method under mild conditions. The scanning electron microscopy (SEM), Fourier transform infrared spectroscopy (FT-IR), Raman spectroscopy (RAMAN), X-ray diffraction (XRD) and X-ray photoelectron spectroscopy (XPS) were used to study the morphology, coating content, thermal properties, and stability in ethylene glycol solution for the composite particles. The results show that HMDA and CCh can modify the surface of CL-20 crystal under mild conditions and form a dense PCHA coating layer. The content of PCHA is about 1% measured by dissolution weighing method and high performance liquid chromatography (HPLC). The PCHA coating layer increases the crystal transition and thermal decomposition temperature by 16 ℃ and 7 ℃, respectively. The thermal decomposition activation energy Ea at different heating rates was calculated by Kissinger method. The activation energy of CL-20@PCHA is about 8 kJ·mol-1 higher than that of CL-20, and the thermal stability is greatly improved. The XRD test results indicate that the PCHA film can effectively prevent the contact between the solvent and CL-20, slow down the dissolution rate of CL-20 in the solvent, and effectively inhibit the crystal transformation of CL-20.

-

PAN Chang-xin, LIU Feng, BI Ru-jie, DAI Wei, ZHU Zheng-de, CHENG Yu-hang

Online:January 17, 2024 DOI: 10.11943/CJEM2023219

Abstract:In order to study the effect of high pressure from screw pumping and medium deep hole charging on the microstructure and thermal stability of the on-site mixed emulsion explosive matrix, the microstructure, particle size distribution, crystallization content, thermal decomposition process, thermal decomposition reaction activation energy, thermal decomposition mechanism function and rate equation of the matrix under atmospheric and high pressures were studied by optical microscope, laser particle size analyzer, water solubility experiment, thermogravimetry and derivative thermogravimetry (TG-DTG) couple method, Kissinger method and Ozawa method, Coats-Redfern method and ?atava method. The results show that from atmospheric pressure to high pressure, polymerization, demulsification and crystallization of the intra-matrix phase droplets appeared, the particle size increased from 3.717 μm to 4.474 μm, the precipitation amount of ammonium nitrate crystals increased from 0.0530 g to 0.0640 g, and the uniformity of the emulsion system was weakened. The average thermal decomposition onset temperature of the matrix Tonset increased from 157.4 ℃ to 184.0 ℃, the average first-order derivative thermogravimetric peak temperature Tp increased from 262.6 ℃ to 281.8 ℃, the average mass loss rate increased from 0.1454 %·s-1 to 0.1476 %·s-1, and the reaction activation energy decreased from 108.49 kJ·mol-1 to 84.74 kJ·mol-1. The free water released by evaporative demulsification under high pressure might cause the rise of Tonset and Tp, and the thermal decomposition reaction was more likely to occur. The activation energy calculated by the Ozawa method had a different trend with the increase of conversion rate, and the thermal decomposition reaction mechanism function changed from Valensi equation to inverse Jinder equation and the rate equation also changed. The high pressure promotes the process of droplet polymerization, demulsification and crystallization of the intra-matrix phase, reduces the activation energy of the thermal decomposition reaction, and weakens the homogeneity and thermal stability of the system.

-

LIU Heng-yan, LIANG Zheng-feng, RUAN Xi-jun, CHENG Shu-jie

2024,32(7):683-692, DOI: 10.11943/CJEM2024023

Abstract:The distribution of initial fragment velocity in the aim direction is one of the important factors for evaluating the power of the directional warhead. Therefore, the calculation method of the initial fragment velocity in the whole domain on the directional side of the warhead under the eccentric double-line initiation and the kinetic energy gain compared with the central initiation are studied. Based on the infinitesimal theory, the calculation method of the initial fragment velocity in different circumferential position on the directional side was derived, and the static explosive experiment of the warhead was carried out to compare with the theoretical result. Combined with the numerical result of the warhead, the axial velocity correction function was fitted, and the universality of the algorithm was verified according to the existing research. It is shown that the proposed formula is suitable for the warhead with eccentric double-line initiation, and the error between theoretical calculation and test results is within 4.80%, calculation result is consistent with actual situation. The fitting correction function can predict the initial velocity of the fragments in different axial direction. The algorithm still has good universality when the warhead parameters change and the calculation error is less than 7.11%. Compared with central initiation, the eccentric double-line initiation mode with an angle of 60° can increase the total kinetic energy of the fragments in the range of -30°-30° from the center of the directional side by 34.9%.

-

LI Zhi-feng, LIN Li, ZHANG Wei-bin, ZHAO Wen-xia, MA Zhi-yuan, LI Hai-ning

2024,32(7):693-701, DOI: 10.11943/CJEM2024089

Abstract:In order to break through the current limitation of simulation accuracy for the ultrasonic detection of TATB based PBX and to realize the structure-performance relationship based nondestructive ultrasonic testing and characterization, an ultrasonic simulation method based on CT image modeling (MBCT) was proposed. Using the significant difference of gray-level distribution between the particle phase and the binder phase in CT images, the structural morphology and features of the sample were extracted. A two-dimensional geometric structure model containing molding powder particles and boundary morphology was obtained by processing the CT slice image with noise reduction, binarization and boundary optimization. Then, the model was used for finite element simulation of ultrasonic propagation, and the differences between MBCT and conventional Voronoi model were quantitatively compared. Results show that the MBCT can effectively and precisely describe the random complex structure characteristics of TATB particles and boundary morphology, which makes the ultrasonic simulation results have better consistency with the experiment ones. The errors of sound velocity, attenuation, frequency domain amplitude and apparent integrated backscattering (AIB) coefficient were 0.32%, 1.14%, 0.92% and 1.55%, respectively (within 2%). Compared with Voronoi model(2.77%, 35.93%, 20.70%, 13.68%), the error is greatly reduced, and the simulation accuracy is significantly improved.

-

SONG Liang, CHEN Bo-cong, ZHANG Yong, SU Hao-long, Hou Fang-chao, YE Jing, SHE Chong-chong

2024,32(7):702-710, DOI: 10.11943/CJEM2024098

Abstract:In order to describe the characteristics of the crystal morphologies of hexogen (RDX), octogen (HMX), and hexanitrostilbene (HNS), the unified kinetic three-dimensional partitioning method was used to simulate the real-time growth morphologies of these three energetic material crystals. The influence of crystal growth conditions on crystal morphology and the topology of crystal face were studied. The research results show that the predicted crystal shape of RDX is rhombus-like, with the main crystal faces being (0 1 0), (1 0 0), and (1 1 0). The crystal morphology of HMX exhibits a columnar shape, with the main crystal faces including (0 1 1), (0 1 0), and (1 1 -1). The crystal morphology of HNS has a flake-like shape, with the (1 0 0) face having the largest exposed area. The predicted crystal morphologies of energetic materials are consistent with experimental results. When RDX, HMX, and HNS crystals exhibit 2D nucleation and growth modes, a higher driving force (Δμ=418.59 kJ·mol-1) causes the molecular layers of the crystal to continuously stack, resulting in layered growth. When the temperature is low, growth units first attach to the crystal faces in the platform area, gradually forming "island-like" agglomerations, followed by epitaxial growth. When the crystal face is sufficiently large, multiple "island-like" structures of different sizes may appear, gradually merging over time. At lower driving force (Δμ=27.21 kJ·mol-1), HNS crystals exhibit spiral dislocation growth, where the (1 0 0) crystal face triggers lamellar growth through a spiral axis, resulting in "terraced" crystal face. Adsorption ability analysis reveals that the kink sites and step surfaces of the helix have strong adsorption ability, while the sites on the face have weak adsorption ability.

-

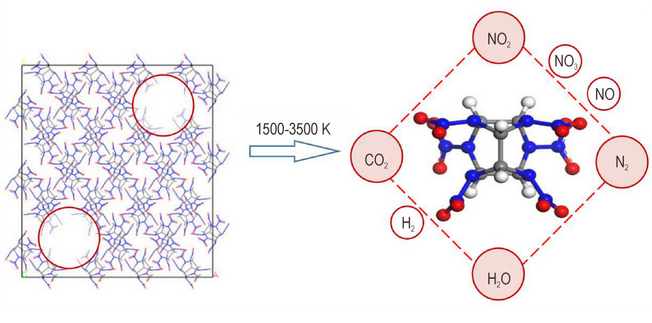

GAN Qiang, ZHANG Wen-bo, WANG Ya-jun, LIANG Lin, REN Shu, LI Gen, HE Jia-jun, FENG Chang-gen

2024,32(7):711-725, DOI: 10.11943/CJEM2024063

Abstract:Isowurtzitane derivatives are currently one of the most potential cage energetic compounds.In order to systematically study the high temperature thermal decomposition law of isowoodsane derivatives and clarify their detonation mechanism, in this work, the thermal decomposition properties of hexanitrohexaazaisowurtzitane (ε-CL-20), 4,10-dinitro-2,6,8,12-tetraoxa-4,10-diaztetracyclododecane (TEX) and 4,10-diazomethyl-2,6,8,12-tetranitrohexaazaisowurzane (BATNIW) under high temperature(1500-3500 K) were studied by molecular dynamic simulations with ReaxFF-lg reactive force field and molecular dynamics method. The results show that the denitro and ring opening are the main initial reactions of ε-CL-20, TEX and BATNIW, in which the ring opening mainly occurs at the C─N bonds or C─O bonds of the five membered rings. Among the decomposition products, the yields of CO2 and H2 change significantly under different temperature, while content of N2 are similar at temperature higher than 3000 K. The decomposition of BATNIW produced N2 with the highest reaction rate and the maximum yield. During the thermal decomposition of TEX, clusters could easily be produced, and glyoxal could be regarded as its characteristic product. The order of thermal decomposition activation energy of the three derivatives is TEX > BATNIW > ε-CL-20, which suggests TEX shows the best stability. This work preliminarily reveals the relationship between the molecular structure and thermal decomposition of three isowurtzitane derivatives.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

-

CAI Jing-jing, XU Xuan, CHEN Zhan-yang, YANG Jun

2024,32(7):726-736, DOI: 10.11943/CJEM2023196

Abstract:In order to explore the influence of the radial air gap in the hole on the directional penetration effect of shaped charge with/without metal liner and the detonation energy transfer process of explosive, ANSYS/LS-DYNA software was used to carry out the numerical simulation study when the air gap of the charge in the hole was 6, 8, 10, 12, 14 cm. The process of centralized release of energy from the shaped charge with metal liner forming an EFP and without metal liner forming concentrated detonation product flow as well as the depth of directional penetration into the borehole wall, was analyzed. The results show that when the air gap is less than 10 cm, the penetration depth of concentrated detonation product flow into the hole wall is increased by 53% (6 cm) and 29% (8 cm), respectively, compared with the average penetration depth of EFP. When the air gap was greater than 10 cm, the average penetration depth of EFP increased by 26% (12 cm and 14 cm) compared with the concentrated detonation product flow. The kinetic energy of EFP and concentrated detonation product flow per unit area through the hole wall on the shaped energy axis was calculated, it is found that when the air gap is small, the energy dissipation of concentrated detonation product flow in the air is less than that of EFP plastic deformation, and the penetration effect of concentrated detonation product flow on the hole wall is better. When the air gap is large, the density and kinetic energy at the axis of the concentrated detonation product flow are significantly reduced due to the spatial expansion of detonation products, while the EFP has high density and incompressibility, small energy dispersion and slow decay of kinetic energy, so the penetration effect of EFP on the hole wall is better than that of the concentrated detonation product flow.

-

WANG Wei, DONG Xiao-fen, WANG Duan, LI Qian, LI Si-yu, GUO Yu-xuan

2024,32(7):737-744, DOI: 10.11943/CJEM2023254

Abstract:The velocity of the flyer is a key factor in determining the reliability of initiating exploding detonators. In order to investigate the influence of barrel parameters on the flyer velocity, the factors affecting the flyer velocity were analyzed through both experimental and numerical simulation methods. A TiW/Ni/Au composite film exploding foil with a film thickness of 0.5/0.5/2 μm and dimensions of 0.15 mm×0.15 mm was designed and prepared using magnetron sputtering technology. Under excitation conditions of 0.1 μF and 1200 V, a polyimide flyer with a density of 1.45 g·cm-3 and a thickness of 25 μm was selected, and the flyer velocities with different barrel parameters were measured using photon Doppler velocity testing technology. The research results indicate that, under the same diameter conditions, the flyer velocity initially increases and then decreases with increasing barrel thickness, reaching a peak at 0.4 mm. When the barrel diameter are 0.15, 0.23, 0.3, 0.35, 0.45 mm, the flyer velocity decreases as the diameter increases, with the highest velocity observed at a diameter of 0.15 mm. Furthermore, under the same thickness and diameter conditions, the velocities obtained from polyimide and ceramic barrel tests exhibit similar trends and values, with polyimide demonstrating higher strength and toughness and lower cost, making it a viable alternative to ceramic as a barrel material. Furthermore, a numerical simulation method was used to re-fit the empirical formula for flyer velocity applicable to the TiW/Ni/Au composite thin film, and the verification results show that the deviation between the calculated results and experimental data is within 2.5%.

-

ZUO Yi-wen, CHEN Jian-bo, LIU Xiao-feng, LIU Yu, SUO Zhi-rong

2024,32(7):745-753, DOI: 10.11943/CJEM2024046

Abstract:Traditional methods are difficult for the purification of TATB due to its poor solubility. Green deep eutectic solvent (CS-1) displays good solubility toward TATB, so CS-1 was used as the solvent with water as back extractant to develop a new purification method for TATB in this study. The difference between this method and other methods were investigated for the purification of TATB. Purification conditions including the amount of back extractant, washing times and drying methods were comprehensively optimized to improve the purity of TATB. Finally, a new method has been established for highly efficient separation and green purification of TATB. Through this method, high-purity TATB was obtained with the purity of (99.7±0.2)% and good recovery of 92.5%. Further, spectroscopic monitoring was combined with theoretical simulation to study the kinetics of the purification of TATB, and then a purification mechanism has been proposed, which is based on the dissociation of TATB’s complexes through the competition of hydrogen bonding between CS-1 and water.

-

Anti-hygroscopic Technology for Ammonium Dinitramide (ADN) Based on Its Cationic Regulation Strategy

PENG Pan-pan, QU Wei-chen, DU LI Xiao-song, SHI Shu-jing, ZHAO Xin-yan, LI Lei, DU Fang, TAO Bo-wen, LI Hong-xu

2024,32(7):754-760, DOI: 10.11943/CJEM2024081

Abstract:Ammonium dinitramide (ADN), as a highly promising new oxidant, is still difficult to achieve large-scale applications due to its strong hygroscopicity. Numerous studies show that the strong hygroscopicity of ADN is mainly attributed to the formation of hydrogen bonds between NH4+ cations and water molecules in air. In this work, a novel dinitramide energetic ionic salt (DBDN) containing divalent cation was synthesized by a simple, safe and efficient one-pot reaction using terephthalaldehyde (TPA), aminoguanidine hydrochloride (AGC) and ADN as raw materials through Schiff base reaction and ion exchange reaction. The product was characterized by elemental analysis, infrared spectroscopy, and nuclear magnetic spectroscopy. Its physical and chemical properties were tested by thermal analysis, mechanical sensitivity testing, and theoretical calculations. In addition, the hygroscopicity of ADN and DBDN was studied by using the desiccator equilibrium method. The impact sensitivity (IS), friction sensitivity (FS) and thermal decomposition temperature (Td) of DBDN are >40 J, 16% and 225 ℃, respectively. The stability of DBDN is much better than that of ADN (5 J, 76% and 198 ℃). Under the conditions of 25 ℃ and relative humidity (RH) of 66% and 75%, after 9 days, the hygroscopic rates of the ADN are as high as 24.1% and 39.5%, respectively, while those of DBDN are only 0.26% and 0.48%, showing non-hygroscopic properties of DBDN.

-

YAN Yi-teng, SUN Shan-hu, LIU Shan, JI Ying-xu, BAI Sen-hu

2024,32(7):761-771, DOI: 10.11943/CJEM2023262

Abstract:Branched glycidyl azide polymer (BGAP) has higher relative molecular mass, wider adjustment range of hydroxyl functionality (f), higher heat of formation and lower viscosity than linear glycidyl azide polymer (GAP). It can increase the energy level, and improve the processing and mechanical properties of the composite solid propellant. Therefore it has become a hot research topic in the field of the azido polyether binder. However, the essentially important key to obtain high quality BGAP energetic binder is how to control and regulate some structural parameters such as hydroxyl functionality, molecular weight and molecular weight distribution. This paper illustrates two synthetic methods and processes of BGAP, proposes the possible reaction mechanism, and summarizes the progress in performance research. Some problems and deficiencies are pointed out. Finally, the development prospects of BGAP in the field of synthesis and performance research are forecasted. It is concluded that optimizing the extraction procedure after reaction, improving the throughput per run, and strengthening the studies in fundamental performance and application will be the focuses in future researches.

-

NAN Ce, ZHAO Peng-cheng, ZHANG Zhi-yue, WANG Yi-fei, WANG Zong-xing

2024,32(7):772-783, DOI: 10.11943/CJEM2024011

Abstract:Gunshot residue (GSR) is an important concomitant product of gun firing, and the analysis of GSR is of great significance in the investigation and litigation of gun-related cases. The traditional GSR test mainly focuses on the inorganic substances produced by primer, but neglects the organic gunshot residue (OGSR) from the propellant. Due to the widespread presence of metal particles in the environment and the production and application of non-heavy metal ammunition, conventional detection methods are prone to false positive or false negative problems. The trace detection technology of OGSR is becoming a research hotspot. The research progress of trace OGSR detection in recent years was reviewed. The advantages and limitations of Raman spectroscopy, mass spectrometry, liquid chromatography-mass spectrometry and electrochemical method in OGSR detection were discussed. The application of chemometrics in trace OGSR detection was introduced. Among them, liquid chromatography-mass spectrometry (LC-MS) is a simple pre-treatment method for OGSR detection with low detection limit and high sensitivity. In the future, the focus of research is to combine the large amount of data obtained based on liquid chromatography-mass spectrometry with the data processing technology of chemometrics to build a detection technology with rapid analysis and identification of OGSR samples.

Vol, 32, No.7, 2024

>Calculation and Simulation

>Pyrotechnics

>Preparation and Property

>Reviews

-

-

-

-

-

-

-

Propellant

2021-2023 Collection

-

Gun Propellant

2021-2023 Collection

-

Safety and damage study

2021-2023 Collection

-

Initiator and Pyrotechnics

2021-2023 Collection

-

Preparation and Property

2021-2023 Collection

-

Crystal and microscopic analysis

2020-2022 发表

-

Chemical Propellant

2021-2022 Collection

-

-

-

-

Eco-friendly technology

2021-2022 Collection

-

Initiating explosive device technology

2021-2022 Collection

-

Damage and ignition

2021-2022 Collection

-

Thermal decomposition,safety performance and evaluation

2021-2022 Collection

-

Preparation and performance—Characterization of molding materials

2021-2022 Collection

-

Preparation and performance—Characterization of synthesis

2021-2022 Collection

-

Preparation and performance—Study on synthesis and performance

2021-2022 Collection

-

Explosion and damage

2021-2022 Collection

-

Detonation physics of energetic materials

2021-2022 Collection

-

High efficiency destruction technology

2021-2022 Collection

-

Propulsion and projection—Propulsion Materials structure and activity relationship

2021-2022 Collection

-

Propulsion and projection—Preparation and performance about propulsion materials

2021-2022 Collection

-

Calculation and simulation—Material structure and response

2021-2022 Collection

-

Calculation and simulation—Structural evolution of materials

2021-2022 Collection

-

Calculation and simulation—Material performance prediction

2021-2022 Collection

-

-

-

-

-

-

-

-

-

Special Issue

Special Issue Virtual Special Issue

Virtual Special IssueCJCR