- Online First |

- Articles in press |

- Current Issue |

- Special Articles |

- Archive

-

LU Qiu, PENG Yong, WANG Zi-guo, CHENG Hao, LI Xiang-yu, LI Zhi-bin

Online:June 28, 2025 DOI: 10.11943/CJEM2025072

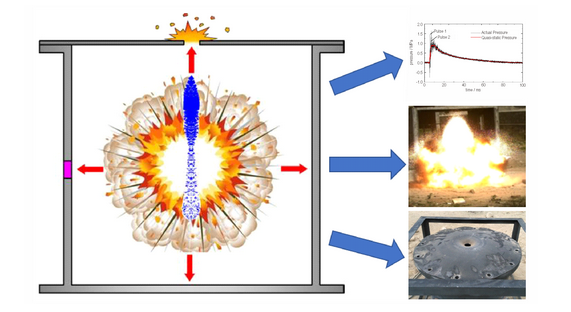

Abstract:In order to attenuate the blast shock wave in the tunnel efficiently, the design idea of setting up multiple continuous diffusion chambers in the tunnel was proposed. Based on the numerical simulation method, the influence of the structural parameters of the multi-stage diffusion chamber on the wave absorption efficiency was systematically discussed, and the propagation attenuation characteristics of the shock wave with a pressure of 2-11 MPa and a positive pressure duration of 18.25-1000 ms in the pit containing single, double/tertiary diffusion chamber were investigated. The results showed that the increase in the number of diffusion chambers can effectively improve the wave dissipation efficiency of the tunnel, and the peak pressure of the shock wave after passing through the three-stage diffusion chamber pit is 81.08% lower than the peak pressure of the straight pit without diffusion chamber with the same length, while the spacing between the diffusion chambers has a limited effect on the wave dissipation efficiency of the tunnel. Under the condition that the total length of the diffusion chamber is equal, the tertiary diffusion chamber has the best attenuation effect on the shock wave compared with a single long diffusion chamber and the secondary diffusion chamber. With the increase of shock wave pressure under the same positive pressure duration, the wave dissipation efficiency of the multi-stage diffusion chamber pit slowly increases. Under the same peak overpressure condition, the wave loss efficiency of the three-stage diffusion chamber pit decreases greatly with the increase of positive pressure time, but it can still maintain a wave loss efficiency of 43.38% when the positive pressure time is 1000 ms.

-

ZHANG Pei-wei, YANG Hai-jun, JIANG Tian-yu, CHEN Shi-luo, LIU Tian-lin

Online:June 28, 2025 DOI: 10.11943/CJEM2025054

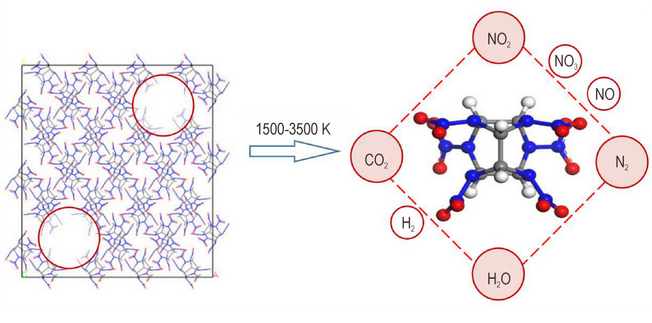

Abstract:Tetraazabicyclo molecules have attracted extensive attention from synthetic energetic materials researchers due to their high density and detonation performance. To expand the types of skeletal structures of tetraazabicyclo molecules and explore the intrinsic relationships between different skeletal structures, in this study, nitroguanidine, glyoxal and urea were used as raw materials to construct a tetraazabicyclo framework by two-step cyclization reaction, and then nitration was carried out to obtain 2-nitro-3-keto-7-nitroimino-2,4,6,8-tetraazabicyclo[3.3.0]octane(4). This compound is a novel tetraazabicyclic molecule incorporating both glycoluril and nitroguanidine structural motifs. The structure of the intermediates and target compounds was confirmed through fourier transform infrared spectroscopy, nuclear magnetic resonance, elemental analysis, and X-ray single crystal diffraction. The intermediate crystal

3·0.5H2O and the target compound crystal4 were obtained. Among them, the crystal of compound 4 belongs to the triclinic crystal system, P-1 space group, with a density of 1.881 g·cm-3 (150 K), and with unit cell parameters of a=6.5172(3) Å, b=9.4087(4) Å, c=13.6334(5) Å, α=γ=90°, β=102.542(2)°. Compound4 was tested by TG-DSC simultaneous thermal analysis, and its enthalpy of formation and detonation properties were calculated using atomization method and EXPLO5 software, and its mechanical sensitivity was tested by BAM method. The results showed that the thermal decomposition temperature of compound 4 reached 243 ℃, the theoretical detonation velocity and detonation pressure were 8538 m·s-1, 30.17 GPa, and the impact sensitivity and friction sensitivity were 10 J and 120 N, respectively. It has good detonation performance and thermal stability. -

CHENG Bing, YE Fu, WANG Quan, XU Ying, CHENG Yang-fan, LI Hong-wei, WANG Meng-xiang

Online:June 26, 2025 DOI: 10.11943/CJEM2025040

Abstract:To study the mechanisms of rock breaking and cavity formation by hole-inner layered charge blasting, the influence of hole-inner layered charges on the rock breaking and cavity formation of deep hole cutting was first investigated through theoretical analysis and model experiments. Then, numerical simulations were carried out using SPH-FEM algorithm to reveal the processes of rock breaking and throwing as well as the mechanisms of rock breaking and cavity formation. Finally, field tests were conducted to explore its application effects. The results show that the hole-inner layered charge could realize the uniform distribution and release of explosive energy, which could eliminate the large rock in the upper cavity and weaken the constraint effect of the surrounding rock in the bottom cavity, so as to achieve the cavity formation efficiency of 96.5%. The numerical simulation realized the visualization of the blasting process. The simulation results confirmed the beneficial effect of uniform energy distribution and sequential release on rock breaking and cavity formation. Compared with traditional cutting blasting technique, using the hole-inner layered charge cutting technique, cycle footage and hole utilization were increased by 0.45 m and 17.3%, respectively, the specific charge and detonator were reduced by 0.42 kg·m-3 and 0.21 PCS·m-3, respectively. The results demonstrated the applicability of hole-inner layered charge cutting technique in deep hole blasting.

-

ZENG Xiao-yun, MU Hui-na, QIN Guo-sheng, WANG Yin, LI Xiao-gang

Online:June 18, 2025 DOI: 10.11943/CJEM2025043

Abstract:Aiming at the reliability evaluation of the energy transfer interface of pyrotechnic sequence, a reliability evaluation method based on fiducial inference method was proposed. This method fully considered the randomness characteristics of the energy transfer interface data. By constructing the probability distribution model of the performance parameters, the prior knowledge was organically combined with the test data, and the accurate evaluation and randomness quantification of the interface reliability were realized. Firstly, the reliability model of the energy transfer interface of pyrotechnic sequence was established. On this basis, the reliability evaluation algorithm framework based on fiducial inference was designed. In order to verify the effectiveness of the proposed method, the evaluation results of the quantile correction method and the Monte Carlo method were compared and analyzed. The results show that when the sample size is 3 to 70, the deviation between the evaluation results based on the fiducial inference method and the true value is the smallest, demonstrating good convergence and stability. Especially when the sample size is less than or equal to 10, this method shows significant advantages, which effectively overcomes the dependence of traditional methods on sample amount, and provides a new method for the reliability evaluation of the energy transfer interface of pyrotechnic sequences.

-

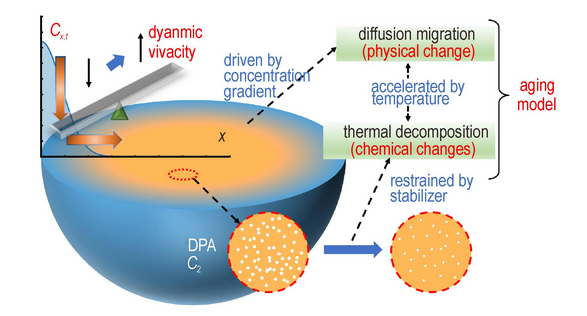

Online:June 13, 2025 DOI: 10.11943/CJEM2025044

Abstract:Carotenoids, valued for their exceptional free radical scavenging properties and low biological toxicity, were systematically investigated as potential stabilizers for propellants. A comprehensive evaluation strategy, incorporating differential thermal analysis (DTA), methyl violet test strips, isothermal thermogravimetry, vacuum stability testing, and accelerating rate calorimetry (ARC), was employed to assess their stabilizing effects. Four representative carotenoids-lycopene, β-carotene, xanthophyll, and astaxanthin, were examined for their stabilization performance in nitrocellulose (NC) and absorptive composition systems. All tested carotenoids demonstrated superior thermal stability compared to conventional stabilizers. Notably, astaxanthin exhibited the most significant enhancement: it prolonged the methyl violet discoloration time of NC by 40 min, reducing mass loss by 17.90%, decreased the maximum adiabatic decomposition temperature rise rate by 0.134 ℃·min-1, and lowered gas pressure release per unit mass by 12.0 kPa. In absorptive compositions, it extended the methyl violet discoloration time by 34 min while reducing mass loss by 14.18%. Free radical scavenging tests and intermediate structural analyses revealed the underlying stabilization mechanism: carotenoids effectively suppress autocatalytic decomposition via nitrogen-oxygen free radical capture, achieving nearly 90% scavenging efficiency at 8 mmol·L-1. Additionally, secondary derivatives formed during carotenoid degradation were free of nitrosamine groups, significantly reducing toxicological concerns.

-

LIU Jian, BAI Fan, ZHANG Long-hui

Online:June 13, 2025 DOI: 10.11943/CJEM2025021

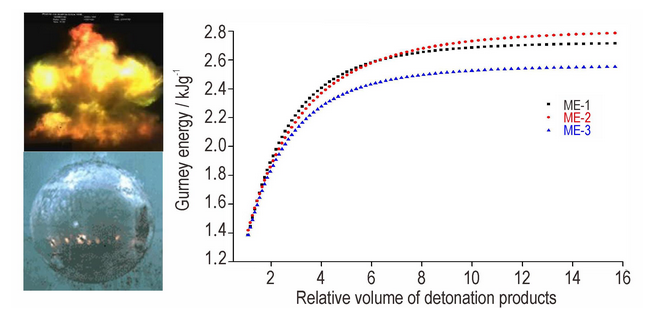

Abstract:The pressure of underwater near-field explosion is high and damping rapidly, which is difficult to test accurately. To investigate the near-field explosion shock wave loading and driving characteristics of aluminized explosives, a model was established to calculate the incident shock wave pressure according to the theory of strong shock wave driving air-backed metal plate . Firstly, the free-field shock wave pressure at 2 R0-6 R0 (charge radius) distance of spherical TNT charges and driving law of 3 mm-thick air-backed steel plate were calculated by numerical simulation. Then the shock wave pressure before cavitation was calculated based on the velocity –time history data. Finally, tests of underwater explosion driving 3 mm-thick air-backed steel plate at 5 R0were conducted on TNT and five different aluminized explosives, which verified the accuracy of the shock wave pressure calculation model. Results also show that for every 5% increase in the content of 2 μm aluminum, the acceleration time of plates increases by 4.4%. With larger particle size of aluminum powder, the acceleration time of plate is longer, but the maximum velocity is smaller. 20 μm and 2 μm aluminum powder absorbs energy in the detonation reaction zone, resulting in a decrease in the detonation velocity and pressure of TNT. While 200 nm aluminum powder may partially participate in the detonation reaction zone and release energy, which positively supports the propagation of detonation waves.

-

ZHANG Yun-feng, GAO Hao-peng, WU Yi-xuan, SUI Ya-guang, LIU Wen-xiang, ZHANG De-zhi

Online:June 13, 2025 DOI: 10.11943/CJEM2024297

Abstract:The fast-running method based on engineering experience is an important tool to assess the explosion damage inside the building structure. To provide the reference for the selection and subsequent improvement of relevant calculation methods, the full-scale confined explosion tests on three-story masonry-concrete building were carried out under two scenarios. The five fast-running methods developed in recent years (i.e. FIST method, charge weight-standoff graphs method, equivalent dynamic load method, energy method, equivalent method) were used to calculate the damage of the buildings. The evaluation indicator and scoring criteria of 5-dimensional calculation ability were put forward. The characteristics of each fast-running method were compared and analyzed. The reasons for the difference in the ability of each method are discussed. Some suggestions for improvement are given. The results show that the charge weight-standoff graphs method is not suitable for the damage assessment of building structure subjected to confined explosions. The FIST method and equivalent method have high accuracy in calculating the masonry wall. The energy method has high accuracy in calculating the RC slabs, but the computational efficiency is low. The calculation efficiency of equivalent dynamic load method is high, but the calculation accuracy is low. In addition, considering the propagation law of the shock wave in complex building structure, improving the scale of numerical simulation are the main way to improve the computing ability of FIST-like and equivalent-like method.

-

WANG Zhe-jun, ZHANG Yan-shen, QIANG Hong-fu, CHEN Jia-xing, WU Rui

Online:June 11, 2025 DOI: 10.11943/CJEM2025049

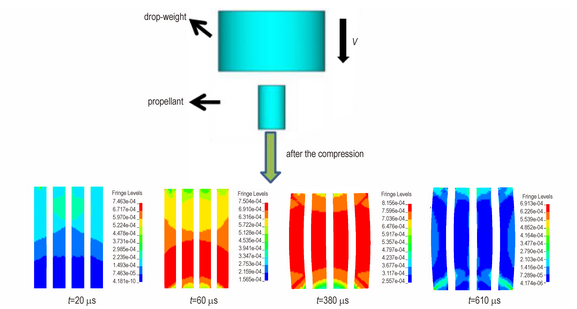

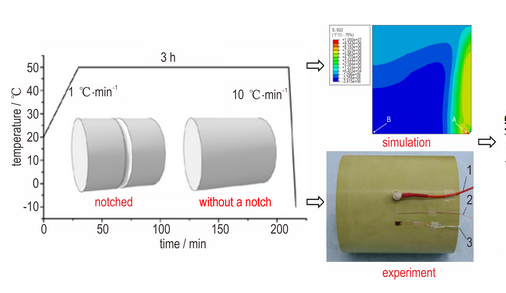

Abstract:To investigate the creep mechanical properties of tri-component hydroxyl-terminated polybutadiene (HTPB) composite solid propellant under different temperatures and stress levels, creep mechanical performance tests were conducted using a self-developed mechanical creep testing equipment, a temperature-humidity environmental chamber, and a high-definition camera. Tests were performed at environmental temperatures of 10 ℃, 25 ℃, 40 ℃ and 55 ℃, covering a stress range of 0.072 to 0.712 MPa . The strain-creep time curves were obtained, along with the variation patterns of typical mechanical property parameters with environmental temperature and stress level. A master curve for the creep rupture time, reflecting the propellant’s failure behavior under broad loading conditions, was established. The results indicate that, as the stress level increases, the characteristics of the propellant’s strain-creep time curve shift from three stages to four stages. Increasing environmental temperature reduces the critical stress level at which the four-stage curve characteristic exhibits, and this stress follows an exponential decay pattern, decreasing from 0.562 MPa at 10 ℃ to 0.262 MPa at 55 ℃ with a reduction ratio of 53.38%. The initial creep compliance increases with rising environmental temperature but remains almost unchanged with increasing stress level. When both environmental temperature and stress level increase, the creep rate increases, creep rupture time shortens, cumulative damage degree increases, and cumulative damage rate accelerates. In contrast, the fracture strain is primarily sensitive to changes in stress level and exhibits a linear increasing trend with increasing stress level. The creep rate under 55 ℃ and 0.412 MPa is approximately 493 times that under the same stress level at 10 ℃, and the creep rupture time is about 2.14% of that under the same stress level at 25 ℃. Finally, based on the double logarithmic test data of creep rupture time versus stress level under different environmental temperatures, and using the environmental temperature-stress level equivalence relationship, a master curve for propellant’s creep rupture time was established. At the same time, exponential mathematical expressions for this master curve and the temperature shift factor were obtained. Calculations using these expressions indicate that, to ensure a vertically stored SRM grain does not experience creep rupture failure within 15 years at 25 ℃, the loading stress level should be lower than 0.2176 MPa.

-

ZHANG Xue-shen, SHEN Xiao-yin, ZHOU Hui, WANG Xue-ren, DING Li, ZHANG Dong-sheng

Online:June 11, 2025 DOI: 10.11943/CJEM2025064

Abstract:Improving the structural integrity of charge is of great significance for ensuring the working stability of solid rocket motor (SRM). Multi-angle tensile loading tests were carried out on the HTPB propellant bonded specimens. During the tensile process, binocular cameras combined with three-dimensional digital image correlation (DIC) methods were used to analyze the deformation field of the bonded specimens. According to the mesoscopic structure of the specimen, a mesoscopic cohesive zone model (CZM) was established and further subjected to numerical simulation analysis, based on three types of damage modes including particle dewetting, matrix fracture and debonding of the bonding interface. The damage evolution law, cracking mechanism and failure mode of the specimen under different tensile and shear stress states were explored. The test results show that the bonded specimen are more prone to damage under the tensile-shear mixed stress state. At the same time, the bearing capacity of the specimen decreases and a greater tensile displacement will occur with increasing the tensile angle. The area where the strain of the bonded specimen is relatively large at the critical state is the location where macroscopic cracks initiate. The numerical simulation results show that the first principal stress is the main factor affecting the generation of cracks in solid propellants, and when the value of the first principal stress is greater than 0.548 MPa, it will lead to the initiation of cracks. Furthermore, the smaller the stretching angle is, the easier the deweeting between the particle and matrix in the propellant is to occur. However, it is easier for the propellant/liner interface to de-bond and the crack propagation location is closer to this interface when the stretching angle increases.

-

Abstract:

-

LI Huan, ZHOU Qi, HOU Tian-jiao, WANG Gui-xiang, LUO Jun

2025,33(6):557-564, DOI: 10.11943/CJEM2025012

Abstract:A novel cage-like energetic compound, 4,4,8,8-tetranitro-2,6-dioxaadamantane, was synthesized via four steps involving oxidative cyclization, oxidation, oximation and gem-dinitration by using 9-oxabicyclo[3.3.1]nona-2,6-diene as raw material. Its structure was characterized by nuclear magnetic resonance(NMR), Fourier transform infrared spectroscopy (FT‐IR) and elemental analysis (EA), and single crystal X-ray diffraction (SC-XRD)was adopted to further confirm its crystal structure. The thermal stability was investigated by differential scanning calorimetry‐thermogravimetry(DSC‐TG)analysis, and detonation parameters were predicted by EXPLO5. Results show that 4,4,8,8-tetranitro-2,6-dioxaadamantane has a crystal density of 1.75 g·cm-3 and belongs to monoclinic system, space groups P21/c. Its thermal decomposition temperature is 190.6 ℃, theoretical detonation velocity is 7705 m·s-1, and detonation pressure is 25.75 GPa.

-

CHEN Zheng-guo, ZHANG Li, ZOU Jia, LI Hao-ran, ZHANG Xiao-tian, XIE Hu-gen, SHI Hai-chuan, ZHOU Qian-zai, HUANG Ming, YANG Hai-jun

2025,33(6):565-572, DOI: 10.11943/CJEM2025024

Abstract:Energetic potassium 3,8-dinitro(pyrazolo[5,1-c][1,2,4]triazin-4-yl)nitramide (

4 ) with a 3-dimensional metal-organic framework (3D EMOF) was synthesized via diazotization, cycloaddition and nitration by using 5-aminopyrazole (1 ) as raw material. Compound4 was characterized and analyzed by nuclear magnetic resonance (NMR), Fourier infrared spectroscopy (FT-IR), mass spectrometry (MS), single crystal X-ray diffraction (SC-XRD), and differential scanning calorimetry (DSC). The friction sensitivity and impact sensitivity of compound4 were tested according to BAM standard. The detonation performance of compound4 was predicted by EXPLO 5 software based on isodesmic reaction. Results show that the crystal of compound4 belongs to monoclinic system, space groups P21/c, exhibits a 3-dimensional metal-organic framework (MOF) structure with a density of 2.021 g·cm-3 at 150 K. Compound4 has a thermal decomposition temperature of 203.4 ℃, a theoretical detonation velocity of 8717 m·s-1, a theoretical detonation pressure of 33.5 GPa, a friction sensitivity of 168 N, and an impact sensitivity of <3 J. -

ZHANG Xin-hui, DENG Mu-cong, ZHANG Chun-jie, HU Shuang-qi, FENG Yong-an

2025,33(6):573-580, DOI: 10.11943/CJEM2025047

Abstract:As an emerging high-energy substance, the development of perovskite energetic materials in both variety and quantity has more urgency. The first perchlorate-based double perovskite energetic material {(C6H14N2)2[Na(NH4)(ClO4)6]}n (DPE-1) and a single perovskite energetic material [(C4H12N2)K(ClO4)3]n (PAP-2) were synthesized by a solution-based method. The chemical structure, thermal stability, detonation performance, and mechanical sensitivity of both DPE-1 and PAP-2 were systematically investigated. Single-crystal X-ray diffraction analysis shows that DPE-1 crystallizes in a double perovskite structure with space group Pa-3, while PAP-2 crystallizes in a single perovskite structure with space group Pnma. Compared with the previously reported periodate-based double perovskite energetic material (C6H14N2)2[Na(NH4)(IO4)6]}n(DPPE-1), DPE-1 exhibits significant improvements in the thermal decomposition temperature (Tdec=368.9 ℃), detonation velocity (D=8858 m·s-1), detonation pressure (p=38.4 GPa), impact sensitivity (IS >40 J), and friction sensitivity (FS=20 N). These results validate the feasibility of exploring high-performance, green primary explosives within the double perovskite structural framework. PAP-2 demonstrates comparable thermal stability (Tdec>280 ℃) and detonation performance (D >8500 m·s-1, p >30 GPa) with other single perovskite energetic materials in the same series, but its impact sensitivity is significantly increased and friction sensitivity is significantly reduced.

-

WU Jun-ying, WANG Jian-yu, LIU Xin-hang, HU Liang, SHANG Yi-ping, LIU Dan-yang, Chen Lang

2025,33(6):581-588, DOI: 10.11943/CJEM2024290

Abstract:Boron powder is often used as a combustible agent in energetic materials due to its high calorific value, volume calorific value and clean combustion products. However, the surface oxide layer of boron powder makes it difficult to ignite and brings low combustion efficiency. In order to improve the ignition and combustion performances, boron powder was wetly milled in hot acetonitrile to remove the surface oxide layer for obtaining pre-treated boron powder with high activity, according to the good solubility of boron oxide in acetonitrile solvent. Acetonitrile and n-hexane were used as a dual control agent, and then the pretreated boron powder and highly active aluminum were performed a secondary ball milling to finally prepare the boron-aluminum composite powder with surface-activated boron. The morphological characteristics, thermogravimetric, ignition and combustion characteristics of boron and composite powder were studied. The results showed that the content of surface boron oxide of boron powder was reduced after pretreatment with acetonitrile, pretreatment boron powder was easier to react with oxygen when heated in air, and the percentage of mass increase was 25.6% more than that of untreated boron powder. After pretreatment with hot acetonitrile, the surface boron oxide content decreased, the active boron content increased, and the ignition and combustion performances were significantly improved. The mass of composite powder with boron-aluminum mass ratio of 60/40 increased by 93% when heated in air, the ignition temperature was 738.1 ℃ at low heating rate, and the particle combustion time was 11.2 ms.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

- 121

- 122

- 123

- 124

- 125

-

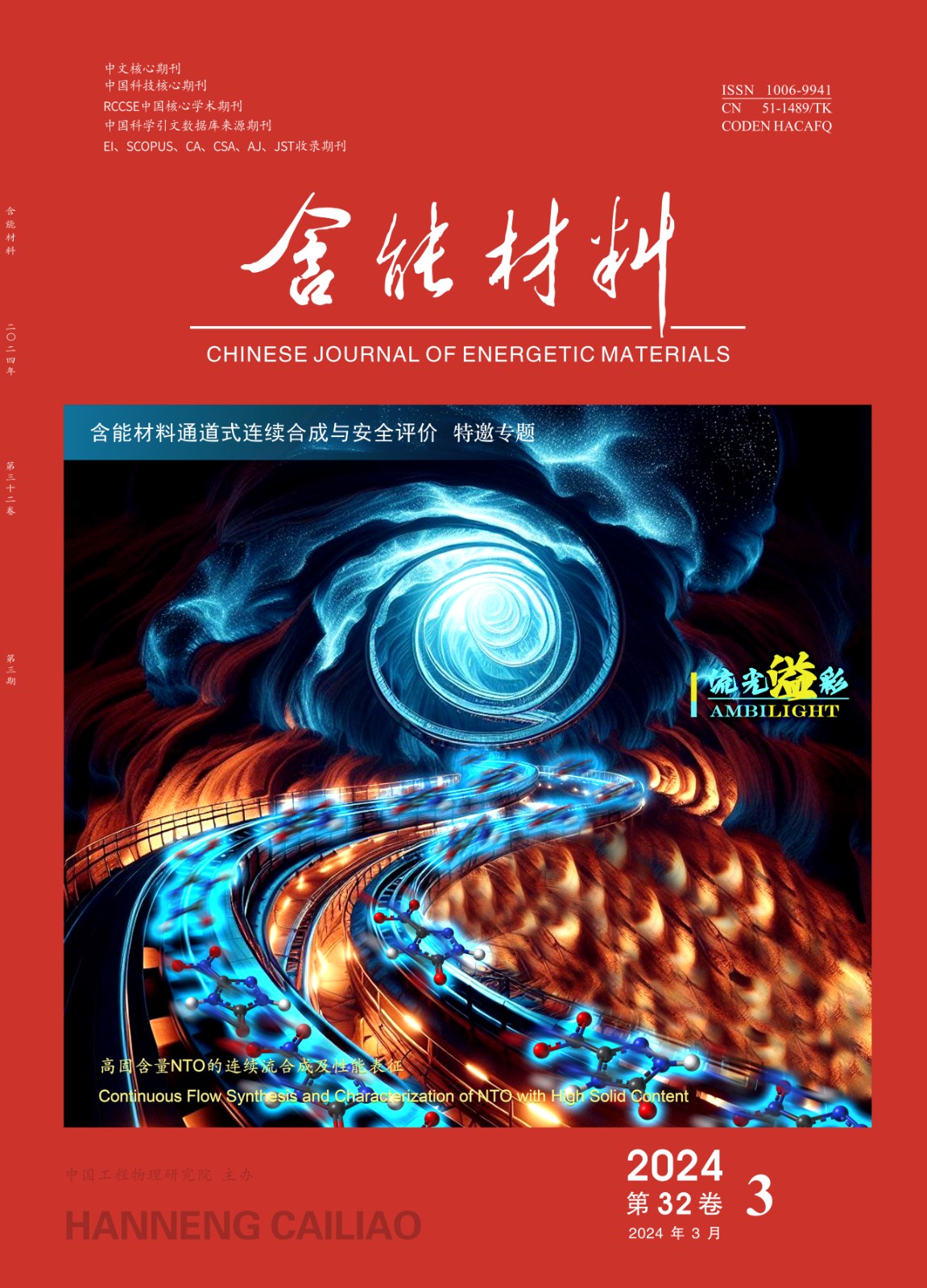

CHEN Wen-cong, DENG Hao-yuan, SHI Qing-wen, ZHANG Zi-yi, SUN Yi, LUO Guo-qiang, SHEN Qiang

2025,33(6):589-600, DOI: 10.11943/CJEM2025008

Abstract:To elucidate the effect of polyvinylidene fluoride (PVDF) content on the combustion performances of aluminum-based solid propellants, Al@PVDF composite powders with coating contents ranging from 2% to 14% were prepared via the solvent and non-solvent method. The thermal reactivity of Al@PVDF composite powders and the energy release and combustion performances of the corresponding solid propellants were analyzed using thermogravimetric-differential scanning calorimetry, constant volume combustion tests, and simultaneous ignition experiments. Results indicate that the PVDF coating significantly enhances the thermal reactivity of aluminum. At the 6% PVDF coating content, the aluminum powder achieves the maximum thermal weight gain and exothermic enthalpy value of 78.96% and 16.14 kJ·g-1, respectively. As the PVDF content increases, the energy release of solid propellants exhibits a trend of initial increase, following by a decrease, subsequent re-increase, and final decline, and reaching the maximum heat release of 6026 J·g-1 and pressurization of 4.45 MPa at 10% coating content. The ignition delay time of aluminum-oxygen reaction decreases from 53 ms to 12 ms. The pressure exponent of burning rate underwent a three-stage evolution, declining from 0.43 to 0.36, and further to 0.26. Analysis of condensed combustion products (CCPs) reveals a stage-dependent mechanism of PVDF content on combustion performances: the low coating content (2%-4%) inhibits molten aluminum agglomeration via pyrolysis products; the medium content (6%-8%) accelerates particle fragmentation and ignition but induces secondary agglomeration; the high content (10%-14%) generates excessive pyrolysis products that promote secondary fragmentation of agglomerates in gas-phase region.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

-

JIANG Yue, LIANG Dao-lun, WANG Jun, WANG Shan, WANG Jian, XU Wang-zi, LIN Ri-chen, SHEN De-kui

2025,33(6):601-609, DOI: 10.11943/CJEM2025065

Abstract:Boron (B)-based composite energetic materials, renowned for their high energy density, are employed in explosives and propellant formulations. In this study, B/ammonium perchlorate (AP)/polyvinylidene fluoride (PVDF) composite energetic microspheres were synthesized using an emulsion-solvent evaporation method, with different PVDF mass fractions (5%, 10%, 15%, and 20%). The surface morphology of the prepared microspheres was characterized via scanning electron microscopy (SEM). To evaluate their combustion behavior, a suspension combustion test was performed using an ultrasonic levitation laser ignition system. Through real-time diagnostics of micro-explosive combustion phenomena, the optimal PVDF content for the enhanced combustion performance was determined. The results revealed that the prepared microspheres possessed a near-spherical morphology and exhibited a three-stage combustion process (developing combustion stage, stable combustion stage and decreasing combustion stage), which was also accompanied by micro-explosions. Among the formulations, the microspheres with 10% PVDF demonstrated the most favorable combustion characteristics, exhibiting the largest flame area and brightness, the highest BO₂ emission intensity (11291.8 counts), the greatest BO₂ peak area integration (12856.8), and the highest surface combustion temperature (1243.8 ℃). These results indicate that the B/AP/PVDF microspheres exhibit optimal combustion characteristics and energy release performance at a PVDF content of 10%.

-

HONG Tian-jiao, KANG Yan, TIAN Peng-fei, XUAN Fu-zhen

2025,33(6):610-616, DOI: 10.11943/CJEM2025009

Abstract:To explore the application of in-situ spectroscopy for monitoring the curing reaction of energetic materials by using toluene diisocyanate (TDI) as curing agent, both In-situ Raman and infrared (IR) spectroscopy were employed to study the spectral changes before and after the curing reaction of 3,3-bis(azidomethyl)oxetane-tetrahydrofuran co-polyether (PBT)-TDI system. The Raman bands suitable for quantitative monitoring of the curing process were analyzed, and the results were evaluated. The vibrational modes of the Raman bands of reactants and products were identified using the density functional theory (DFT) method. The correlation between the curing reaction results obtained from IR and Raman spectroscopy was also discussed. Results show that the peak of 1534 cm-1 in Raman spectroscopy of the PBT-TDI system exhibits a low signal-to-noise ratio, making it unsuitable for quantitative analysis. The reaction degree calculated from the peak of 1743 cm-1 in Raman spectroscopy is significantly higher than that derived from the peak of 2269 cm-1 in IR spectroscopy. The peak of 1505 cm-1 in Raman spectroscopy is associated with the stretching vibration of the isocyanate (NCO) group. The difference in the degree of reaction between Raman and IR is due to the number of individual NCO groups in the TDI molecules that participate in the reaction. The two methods play complementary roles in monitoring the curing process.

-

ZHOU Tao, DU Yan-tao, XIE Xu-yuan, ZHONG Shan-wei, YU Yu-yang, LIU Xiang-yang, ZHOU Dong-mo

2025,33(6):617-624, DOI: 10.11943/CJEM2025028

Abstract:A testing device for measuring the curing shrinkage rate of solid propellants was developed in this study. In addition, the online monitoring test of curing shrinkage of HTPB/IPDI propellant was carried out. The relationship between curing shrinkage and time during the curing process of solid propellant was obtained. By constructing the relationship between curing shrinkage, curing degree and curing kinetics, the curing degree change law and curing kinetics model of solid propellant during curing process were obtained. The results show that the curing shrinkage of solid propellants changes in a three-stage S-type. The maximum curing shrinkage is about 0.108%, and the maximum curing reaction rate is 7.809×10-6. During the isothermal curing process, the curing reaction rate curve of HTPB/IPDI propellant shows a bell-shaped curve, so the thermal curing of solid propellant has autocatalytic characteristics. The pre-exponential factor A0 of the self-catalytic kinetics model for HTPB/IPDI propellant is 379.087 s-1. The reaction orders m and n are 0.711 and 1.501. The results provide a new method to test the shrinkage of propellant and clarify the curing reaction characteristics of composite solid propellants.

-

ZHU Jin-can, WANG Chao, CAO Hong-tao, WANG Dun-ju, ZHANG Hao-bin, LI Shi-chun, JIN Bo, LIU Yu

2025,33(6):625-634, DOI: 10.11943/CJEM2025060

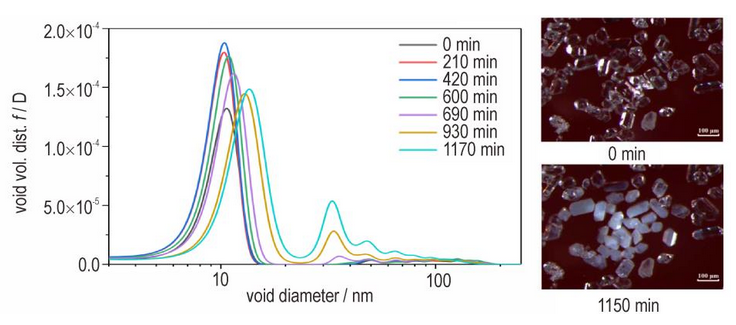

Abstract:Ultrafine hexanitrostilbene (HNS) is widely used in explosion foil initiators and related applications due to its outstanding thermal stability and excellent high-voltage short-pulse performance. However, its high surface energy during service process leads to solid-phase ripening. Previous studies have explored the effects of temperature, residual solvents, and time on the solid-phase ripening of ultrafine HNS, but these investigations primarily focused on isolated or narrowly factors. Currently, no multivariate predictive model has been established. In this study, a predictive model was developed based on previously obtained small angle X-ray scattering (SAXS) data, including specific surface area (SSA) and relative specific surface area (RSSA), obtained under varying temperatures and residual dimethylformamide (DMF) contents. The model was constructed using machine learning algorithms and optimized empirical models. It comprehensively accounts for time, temperature, and residual DMF content in its predictions. The results show that on the training dataset, the random forest (RF) model achieved an R² of 0.9989 in predictions, while the polynomial regression (PR) model and optimized empirical model attained R² values of 0.9091 and 0.9129, respectively. By comparing the prediction performance of these three models, the most suitable model for predicting the solid-phase ripening process of ultrafine HNS was identified. Furthermore, purity tests and scanning electron microscopy (SEM) characterization revealed that particle characteristic variations exert significantly influence on the extent of solid-phase ripening in ultrafine HNS. A predictive method was established for the solid-phase ripening process of ultrafine HNS, laying a foundation for investigating its aging mechanisms and optimizing storage stability.

-

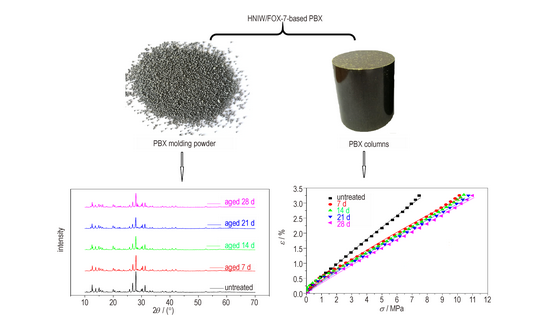

LUO Chun-wang, GOU Rui-jun, YU Xiao-dong, ZHANG Shu-hai, ZHANG Peng, PEI Shui-wang

2025,33(6):635-644, DOI: 10.11943/CJEM2024279

Abstract:In order to investigate the influencing factors of the pressing effect and safety of the irregular-shaped charges, numerical simulation of the pressing process of the irregular-shaped JH-2 charge, with a diameter of D=88 mm, a molding height of H=132 mm, and a wedge angle of α=60°, was carried out by using the dynamics of continuous media method in the Marc finite element software, and the effects of process parameters such as pressing pressure, pressing rate, initial relative density, friction coefficient, and holding time on the forming of the charges, including the molding density and internal stress, were studied systematically. The results show that the density and stress distributions inside the irregular-shaped charge are nonuniform, and there are obvious regions of density loose and stress concentration. The pressing pressure, initial relative density, holding time and friction coefficient affect the molding density and stress distribution of charges simultaneously, while the pressing pressure, initial relative density and pressing rate are the main factors affecting the stress concentration of the irregular-shaped charge. In view of this irregular-shaped structure, when the pressing pressure is 300-350 MPa, pressing rate is 1.5 mm·s-1, initial relative density is 0.65, friction coefficient is 0.15, and holding time is 120 s, the density distribution of the irregular-shaped charge is relatively uniform, and the stress gradient difference is small, which can improve the molding quality, reduce the stress concentration and avoid cracks, and ensure the charging safety.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

-

CAI Can-wei, NING Quan-li, DENG Hai-fei, ZHANG Zhi-wen, LIU Li-wen

2025,33(6):645-657, DOI: 10.11943/CJEM2025023

Abstract:To accurately analyze the interior ballistic performance and launch overload of image terminal guided projectiles, the connotative essence of the firing with different charge numbers was investigated based on the characteristics and working principles of the adaptive launch platform and launch charge. The interior ballistic two-phase flow model for image terminal guided projectile was established, and its rationality was verified through simulations and measured data under two different working conditions. Building on this, the evolution laws of pressure fluctuation and projectile motion in the bore of a certain type of image terminal guided projectile with different charge numbers were analyzed using the verified interior ballistic two-phase flow model. Furthermore, the launch overload characteristics of this type of image terminal guided projectile with different charge numbers were studied through the established engineering calculation model of launch overload. The results show that the relative errors of the maximum pressure at the bottom of the bore and the initial velocity of the projectile between two verification conditions are less than 2%, and the variation laws of the pressure at the bottom of the bore and the pressure wave in the bore with time are highly consistent between simulation and measurement. The internal ballistic performance and launch overload variation laws of the image terminal guided projectile with different charges obtained from the verified model are consistent with the general laws of the actual launching process.

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- 11

- 12

- 13

- 14

- 15

- 16

- 17

- 18

- 19

- 20

- 21

- 22

- 23

- 24

- 25

- 26

- 27

- 28

- 29

- 30

- 31

- 32

- 33

- 34

- 35

- 36

- 37

- 38

- 39

- 40

- 41

- 42

- 43

- 44

- 45

- 46

- 47

- 48

- 49

- 50

- 51

- 52

- 53

- 54

- 55

- 56

- 57

- 58

- 59

- 60

- 61

- 62

- 63

- 64

- 65

- 66

- 67

- 68

- 69

- 70

- 71

- 72

- 73

- 74

- 75

- 76

- 77

- 78

- 79

- 80

- 81

- 82

- 83

- 84

- 85

- 86

- 87

- 88

- 89

- 90

- 91

- 92

- 93

- 94

- 95

- 96

- 97

- 98

- 99

- 100

- 101

- 102

- 103

- 104

- 105

- 106

- 107

- 108

- 109

- 110

- 111

- 112

- 113

- 114

- 115

- 116

- 117

- 118

- 119

- 120

-

FU Hui, SHAN Yu-jia, TIAN Tian, WANG Jin-xin, WANG Tao, ZHANG Wen-quan

2025,33(6):658-670, DOI: 10.11943/CJEM2025006

Abstract:According to the connection mode of molecules and whether the molecule is neutral, the high-energy heat-resistant compounds reported in recent years are divided into three categories: fused ring, linked heterocyclic and ionic. The structural characteristics, synthesis methods, physicochemical properties and detonation performances of three kinds of high-energy heat-resistant compounds are reviewed. and the application prospects are evaluated. The development direction of the synthesis of high-energy heat-resistant compound is prospected: developing universal construction technology of skeleton, promoting the integration of computational simulation and molecular design, and innovating green and efficient synthesis process. It provides a reference for the design and synthesis of new high-energy heat-resistant compounds.

-

WANG Hai-feng, WANG Kang-cai, LIU Yu

2025,33(6):671-680, DOI: 10.11943/CJEM2025076

Abstract:Technological and industrial transformations driven by data science and artificial intelligence are profoundly impacting the field of materials science, presenting both unprecedented opportunities and significant challenges for the innovation of energetic materials. As an emerging technology, machine learning offers novel research paradigm for the molecular design and synthesis of energetic materials. It is expected to solve the long-standing bottlenecks such as low efficiency, high cost, and lengthy development cycles. Although some successful cases have been reported, the application of machine learning across the full research cycle of energetic molecules—design, screening, synthesis, and performance validation—remains in a relatively immature stage compared with the application in other advanced materials domains. This review outlines the current research status of machine learning-assisted development of energetic materials, summarizes its applications in molecular design, single-property prediction, and multi-property simultaneous prediction. Nonetheless, the use of machine learning in design and synthesis of energetic materials with targeted properties remains fraught with challenges. Future efforts should prioritize the control of data quality and the construction of standardization frameworks, the development of interpretable machine learning models, and the establishment of interdisciplinary integration platforms, further promoting the efficient creation of high-performance energetic materials.

Vol, 33, No.6, 2025

>Energetic Express

>Preparation and Property

>Propulsion and Projection

>Reviews

-

-

-

-

-

-

-

-

-

-

Propellant

2021-2023 Collection

-

-

Gun Propellant

2021-2023 Collection

-

Safety and damage study

2021-2023 Collection

-

Initiator and Pyrotechnics

2021-2023 Collection

-

Preparation and Property

2021-2023 Collection

-

Crystal and microscopic analysis

2020-2022 发表

-

Chemical Propellant

2021-2022 Collection

-

-

-

-

Eco-friendly technology

2021-2022 Collection

-

Initiating explosive device technology

2021-2022 Collection

-

Damage and ignition

2021-2022 Collection

-

Thermal decomposition,safety performance and evaluation

2021-2022 Collection

-

Preparation and performance—Characterization of molding materials

2021-2022 Collection

-

Preparation and performance—Characterization of synthesis

2021-2022 Collection

-

Preparation and performance—Study on synthesis and performance

2021-2022 Collection

-

Explosion and damage

2021-2022 Collection

-

Detonation physics of energetic materials

2021-2022 Collection

-

High efficiency destruction technology

2021-2022 Collection

-

Propulsion and projection—Propulsion Materials structure and activity relationship

2021-2022 Collection

-

Propulsion and projection—Preparation and performance about propulsion materials

2021-2022 Collection

-

Calculation and simulation—Material structure and response

2021-2022 Collection

-

Calculation and simulation—Structural evolution of materials

2021-2022 Collection

-

Calculation and simulation—Material performance prediction

2021-2022 Collection

-

-

-

-

-

Special Issue

Special Issue Virtual Special Issue

Virtual Special IssueCJCR